- Local time

- 2:04 PM

- User ID

- 26310

- Joined

- Mar 13, 2023

- Messages

- 1,033

- Reaction score

- 2,910

- Location

- Maryland, USA

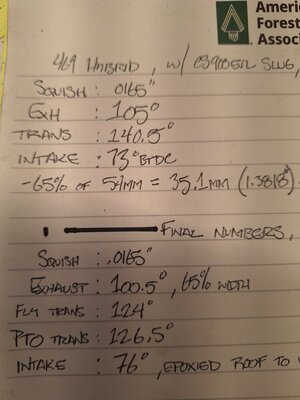

Raising transfers.... Too much blow down for now. And staggered timing. An unnecessary variable added on another novice theory. May be hurting the thing. But, I left room to raise. I'll be back in for sure.

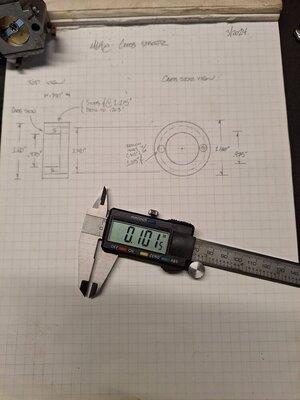

Note the chip in the plating. Chamfered with a diamond. Can't complain as the price was right.

Note the chip in the plating. Chamfered with a diamond. Can't complain as the price was right.