redline4

I'm huge in Japan

- Local time

- 2:50 AM

- User ID

- 5593

- Joined

- Mar 12, 2018

- Messages

- 13,520

- Reaction score

- 114,455

- Location

- Rosholt Wisconsin

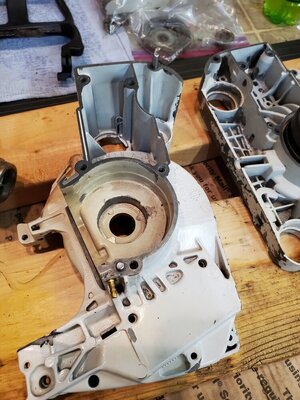

Back to it.

I bolted in the oil pump.

Thought I took a pic, evidently I didnt.didn't..

I turned the oil tube to the side for access to the case bolt behind it for later..

I set it on boards because of the tube.

And threw some heat too it.

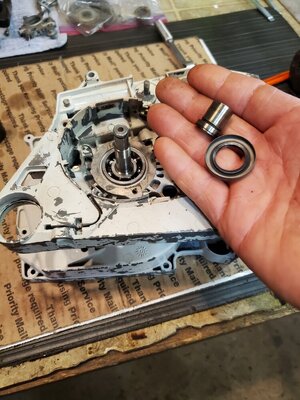

pushed the bearing in (shoulder facing out)..

pushed the bearing in (shoulder facing out)..

And gave it a couple taps to be sure it was seated with my special tool..

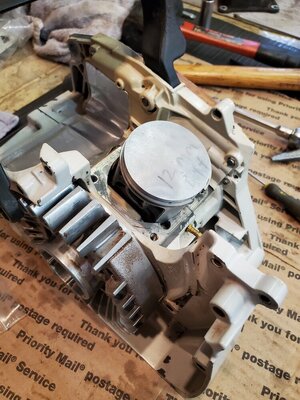

I put a little more heat to it and the crank dropped in.

Couple light taps made sure it went in.

I bolted in the oil pump.

Thought I took a pic, evidently I didnt.didn't..

I turned the oil tube to the side for access to the case bolt behind it for later..

I set it on boards because of the tube.

And threw some heat too it.

pushed the bearing in (shoulder facing out)..

pushed the bearing in (shoulder facing out)..And gave it a couple taps to be sure it was seated with my special tool..

I put a little more heat to it and the crank dropped in.

Couple light taps made sure it went in.