You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HUSQVARNA HUSQVARNA THREAD

- Thread starter P.M.P.

- Start date

- Local time

- 6:38 AM

- User ID

- 568

- Joined

- Jan 17, 2016

- Messages

- 34,489

- Reaction score

- 196,486

- Location

- Wv

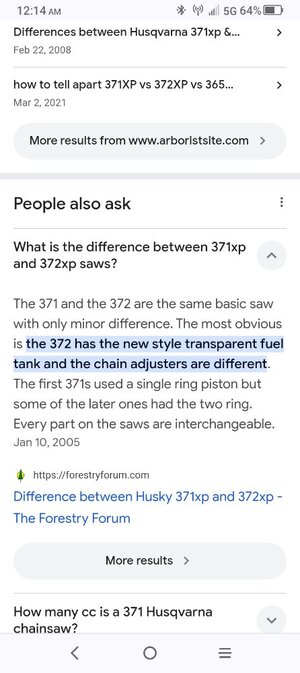

So, picked up a pair today… 371 and a 55. Both in great condition. What are the differences between the 371 and the 372?

It seems they are pretty much the same, spec wise.View attachment 432165

- Local time

- 3:38 AM

- User ID

- 232

- Joined

- Dec 24, 2015

- Messages

- 9,755

- Reaction score

- 67,103

- Location

- Coastal Oregon

So, picked up a pair today… 371 and a 55. Both in great condition. What are the differences between the 371 and the 372?

It seems they are pretty much the same, spec wise.View attachment 432165

The crankcase was also upgraded between the 371/72. There was gusseting added behind the bar pad area due to the 371 crankcases cracking through the bar studs.

- Local time

- 6:38 AM

- User ID

- 568

- Joined

- Jan 17, 2016

- Messages

- 34,489

- Reaction score

- 196,486

- Location

- Wv

And the plastic clips

Weren't orange no more.The crankcase was also upgraded between the 371/72. There was gusseting added behind the bar pad area due to the 371 crankcases cracking through the bar studs.

- Local time

- 5:38 AM

- User ID

- 7214

- Joined

- Sep 4, 2018

- Messages

- 3,760

- Reaction score

- 26,941

- Location

- Central Kansas

The plastic oil pump gear was changed.

- Local time

- 6:38 AM

- User ID

- 568

- Joined

- Jan 17, 2016

- Messages

- 34,489

- Reaction score

- 196,486

- Location

- Wv

Go ahead and have it portedNoticed that

Squareground3691

Here For The Long Haul!

- Local time

- 6:38 AM

- User ID

- 16376

- Joined

- May 1, 2021

- Messages

- 3,307

- Reaction score

- 15,964

- Location

- New England

farminkarman

I like the red & black ones

- Local time

- 5:38 AM

- User ID

- 13535

- Joined

- Aug 17, 2020

- Messages

- 5,027

- Reaction score

- 29,064

- Location

- Neenah Wisconsin

I ended up taking the saw into my dealer and had him reprogram the coil to match the carb and do a firmware update. The saw is running good now.I’m not sure there is anything wrong with the carb & coil…could be I suppose. It would be all be good if the AT could lean out the low circuit. I’m sure it was at max fuel based on the seals or lack thereof when it had last run. It seems like the AT already cleaned up the high circuit….just pig rich on the low side.

Maintenance Chief

Disrupting the peace with an old chainsaw

- Local time

- 6:38 AM

- User ID

- 11378

- Joined

- Jan 4, 2020

- Messages

- 4,215

- Reaction score

- 13,796

- Location

- South Carolina

- Local time

- 4:38 AM

- User ID

- 23623

- Joined

- May 30, 2022

- Messages

- 697

- Reaction score

- 2,122

- Location

- NW MT

qurotro

Cookie Cutter

Just weld it back...572 fuel tank replacement, how hard is it? I keep my saws in a truck tool box and they do bounce around alot, I'm thinking it must have bounced and landed on a nut or bolt or something.

- Local time

- 4:38 AM

- User ID

- 23623

- Joined

- May 30, 2022

- Messages

- 697

- Reaction score

- 2,122

- Location

- NW MT

any recommendation on a product to use?

- Local time

- 4:38 AM

- User ID

- 26178

- Joined

- Feb 23, 2023

- Messages

- 1,808

- Reaction score

- 5,852

- Location

- Montana

A piece of plastic off the saw would work if your into plastic welding. Same for same is what I do. Works for me.any recommendation on a product to use?

- Local time

- 4:38 AM

- User ID

- 23623

- Joined

- May 30, 2022

- Messages

- 697

- Reaction score

- 2,122

- Location

- NW MT

I've never tried to weld plastic before and did think about trying it out, had some seals all epoxy that is made for plastic gas tanks and cans I put on there. I know there is a clapped out 572 at the local husky shop I just a few days ago, it has a couple balls missing from the PTO bearing, I am gonna try to buy the tank from it next week.

Woodwackr

Here For The Long Haul!

- Local time

- 4:38 AM

- User ID

- 28333

- Joined

- Jan 18, 2024

- Messages

- 3,511

- Reaction score

- 16,303

- Location

- ID

JB Marine? Stuff is pretty impervious to chemicals572 fuel tank replacement, how hard is it? I keep my saws in a truck tool box and they do bounce around alot, I'm thinking it must have bounced and landed on a nut or bolt or something.

Woodwackr

Here For The Long Haul!

- Local time

- 4:38 AM

- User ID

- 28333

- Joined

- Jan 18, 2024

- Messages

- 3,511

- Reaction score

- 16,303

- Location

- ID

I haven’t had good luck with plastic welding. Id bet I just don’t have the right tools and knowledge. Got any vids of the procedure along with the necessary tools?Just weld it back...

qurotro

Cookie Cutter

A solder iron with adjustable temp would help. You need to try it by slowly increasing temp, find the sweet spot.I haven’t had good luck with plastic welding. Id bet I just don’t have the right tools and knowledge. Got any vids of the procedure along with the necessary tools?

- Local time

- 5:38 AM

- User ID

- 12238

- Joined

- Apr 13, 2020

- Messages

- 4,044

- Reaction score

- 27,127

- Location

- 5543X, 5644X

Similar threads

- Replies

- 8

- Views

- 692