So I have been reading the info that

@Agent Smith sent me, particularly the entire thread about compression figuring I would find the answer to my question on what is squish/the squish band, however I did not. While I appreciate you sending me your numbers

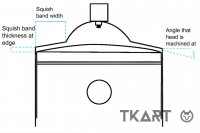

@Red97, I unfortunately need to know more about squish, and even more so how to measure it so I can know how much to take off the base. When it comes to my knowledge of engine modifications, think 16 year old kid who has driven around in a parking lot once or twice but is now out on the road for the first time. I have a very basic understanding of how to make more power but not the specific minute steps to get there. Like, more fuel, combined with more air, pressed together real tight makes a bigger bang, which equals more power, but only if you get the exhaust out fast enough. And now you pretty much know everything I know! I kid, but you get the idea. Haha