- Local time

- 6:43 PM

- User ID

- 2807

- Joined

- Mar 14, 2017

- Messages

- 6,443

- Reaction score

- 16,774

- Location

- Illinois

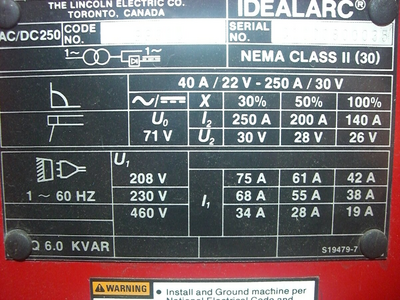

That is the correct plug.Is this a limiting factor? 50 amp welding plug 6-50p. What is the next step-up plug for Amps greater then 50?

View attachment 460733