lehman live edge slab

Live Action

Uncle has a Sears craftsman gas drive from 40’s or 50’s. Has push plugs to change amperage and a 16 hp onan on it that you wrap rope around to start no rewind

Got the PF. I doubt I'll ever run this at 200. 120 was intense. More heat than I have ever seen or witnessed. If I do it will be to satisfy a curiosity.

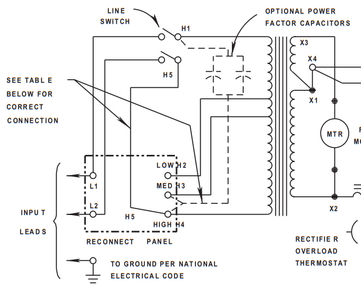

When you say "power factor capacitors' are you refering to a pi filter which is used to smooth out the ripple voltage on the out put ?View attachment 461053

Since this welder is about 25 years old, I would check if the power factor correction capacitors are still OK.

Lots of fords and dodges with a few gm trucks. Lots of oldish trucks too

We have a large vocational program here in the East Moline Illinois school district. The (25) rural school districts around the area can send Junior and Senior students there for 1/2 of the day for a wide array of vocational programs. Since this is the world headquarters for Deere they have their own welding and machine program as part of the system. They monitor students and choose a select few to offer jobs upon graduation.Lots of fords and dodges with a few gm trucks. Lots of oldish trucks too

I think what that deal is the caps are in parrallel with part of the primary winding of the transformer thus cancelling out the inductive reaction of the winding .So it appears it would provide power factor correction to a degree .Evidently then selection of H2 or H3 would change the value of basically the inductor ,the partial winding . I think it would also act as regulation device ,basially a filter similar to the pi configuration .No, those are capacitors placed in parallel on the primary side of the transformer. They allow to reduce the total current flowing in the supply line, which allows to reduce the required gauge of the supply wires and the size of the overcurrent protection.

Of course, the correction is also welcomed by the power company, because it reduces useless current that only heats up the wires and transformers.

View attachment 461063

How do I do that?

I think what that deal is the caps are in parrallel with part of the primary winding of the transformer thus cancelling out the inductive reaction of the winding .So it appears it would provide power factor correction to a degree .Evidently then selection of H2 or H3 would change the value of basically the inductor ,the partial winding . I think it would also act as regulation device ,basially a filter similar to the pi configuration .

I would check them by measuring capacitance using DMM. If I saw correctly in the photo they should be about 26 microfarads. I would check for voltage on them before measuring. Normally there should not be. Of course, this is all after disconnecting the power plug.

Of course, capacitors change the reactance and thus the reactive power. That is their only role there. The welder can work just fine without these capacitors.

Because these types of welders have switchable primary windings to operate with different input voltages, and because the reactance seen by the power line varies greatly depending on the load on the secondary winding (welding current), the capacitors used must be a compromise.

For an input voltage of 230 V and a mains frequency of 60 Hz, the rated input current with capacitors is 68 A, without 86 A.

The power factor for a 200 A load with capacitors is 83.3 (%), without capacitors 69.

But the price for this correction is a much higher input current at idle of 6.2 A vs. 23 A. Of course, the home user does not pay for reactive power.

Wasn’t trying to derail the whole thing just figured that something may be wrong with the welder if it’s tripping a 60 amp breaker at 125 amp setting especially how you describe the weld

I’ve done lots of welding at 125 amps and much higher and that’s why I thought between the popping breaker and the description of how hot the weld was vs the old welder ect it was making me believe maybe something was off with the machine and it was putting out far more than 125 like the dial said. I’m not there to run a bead like many so just going by your descriptions. A person that welds lots would be able to tell you right away if it was anything close to the 125 or way hotter. You can run uphill at 125 amps on heavier plate ect.I thought to correct you earlier, but held off. For the record the setting of the welder was not 125 when the meter breaker popped. I don't recall what it was set at, but under a 100 for sure. The following day I set it at 125 to "Stress" test the welder and to see if a breaker popped. It did not. The only other thing in the garage that might have contributed to the breaker popping was the deep freezer. The following day, I disconnected the freezer before stress testing the welder set at 125. That got me to point the finger at the breaker. And since I had already determined that the box and lines can handle a 90A breaker that it the initial direction I am taking.

I’ve done lots of welding at 125 amps and much higher and that’s why I thought between the popping breaker and the description of how hot the weld was vs the old welder ect it was making me believe maybe something was off with the machine and it was putting out far more than 125 like the dial said. I’m not there to run a bead like many so just going by your descriptions. A person that welds lots would be able to tell you right away if it was anything close to the 125 or way hotter. You can run uphill at 125 amps on heavier plate ect.

That’s a lot to do with open circuit starting voltage, after the rod was burning the actual welding should have been similar between the two at 125. Unless something is wrong with one or the other and that’s why I was thinking a possibility of something wrong inside when it blew a breaker.I routinely ran my Century AC230 over a 100A. If I recall correctly striking an arc at less than 100 was difficult and would not maintain the arc. 130 or so was pretty much the default for the Century. I even bought some 1/16 rods to see if I could get it to weld at even lower settings. Nope! I did once have a Lincoln AC225, and its performance was about equal to the Century. Again, I go back to believing that the $6000 MSRP IdealArc is different. Not just a heavy beast but efficient. If it wasn't then it would be a dust collector at the factory, and finally scrapped.

This is where the new inverter welders shine, I can run beautiful beads at 40amps on exhaust pipe with 7014 rod with no problems starting but other than teaching my boy how to do it I use the mig welder for all work like that. If I use going to be doing a lot of welding tho in the higher amperage can't beat the old transformers.If I recall correctly striking an arc at less than 100 was difficult and would not maintain the arc. 130 or so was pretty much the default for the Century. I even bought some 1/16 rods to see if I could get it to weld at even lower settings. Nope!