OnlyStihl

Super OPE Member

Ya I'll be curious what your amp meter says once you take some readings between the 2 welders.

This is where the new inverter welders shine, I can run beautiful beads at 40amps on exhaust pipe with 7014 rod with no problems starting but other than teaching my boy how to do it I use the mig welder for all work like that. If I use going to be doing a lot of welding tho in the higher amperage can't beat the old transformers.

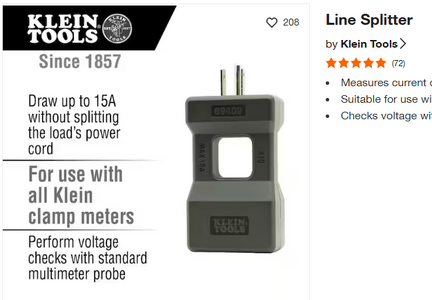

Amp clamp should be showing up today. I plan to make a 240V breakout cable so I can get the clamp over the individual wires. I got the parts, just need to do it.

First measurement is going to be on that old deep freezer. Measure its startup surge and its running usage.