OnlyStihl

Super OPE Member

I don't know about other Europeans, but this is always a weird sight to me.

I guess it is a 110/120Volt area thing?!

We plug any 220Volt single phase appliance into any 220Volt outlet and it has to run/support it.

Of course, there are exceptions where electrical installations apparently weren't up to code and chittt happened - but that is another story.

Welding is different. If it were a range/stove absolutely. With welding all things come into consideration. In my situation coming out of the breaker box is 6AWG, the weakest link. But it's only 3 feet in length, and a 50% duty cycle should allow a temporary/small overload. At least that's how I understand it all. May only be academic, as I burned 1/8 rod at 70amps the other day. This machine feels like it will run a 1/4 rod, were I to weld a steel bridge. Not likely.

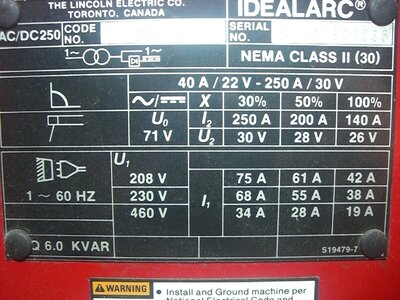

For my own reference (off back of MY machine) :

| Input @Breaker (plate on the back) | Output @Electrode Dial Setting | %Duty Cycle |

| 38Amps | 140Amps (1) | 100% |

| 55Amps (2) | 200Amps | 50% |

| 68Amps (3) | 250Amps | 30% |

(1) Max so far 70Amps, 1/8" rod, 6011

(2) Swap garage breaker with 60Amp

(3) Probably just leave it all alone. (i.e. Don't Use!!!)

If things are linear or close enough, then at the dial 70Amps, I am only taxing my electrical set up at maybe at 1/3 capacity.

On MY machine ->

Last edited: