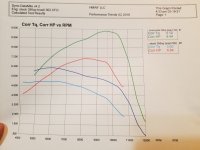

I understand what your saying. The vast majority of saw loose torque at rpm, most are losing from the 5k Mark when joe starts the graph. Some builder gain torque everywhere and some flatten the torque curve out farther, the rarest saws stay flat out into the cutting rpm, the dyno is saying that the torque curve could be shifted higher and gains could be made. Saws aren’t like cars an other Motorsports, were you need acceleration, not that it isn’t desirable as a feel. But it theory, a saw dose not need much torque below its lowest cutting rpm, if a saw could peak just below its lowest cutting rpm and maintain torque to max loaded cutting rpm. That’s not an easy build to achieve.

On your vette, I am a small block guy myself, in my 68 camaro, I chose to soften the torque curve off the bottom, I feel you can’t hook up too much torque, I destroked a 400sb to a 377, did 11-1 comp solid roller cam afr210 cnc heads, I ran several different cam’s through the simulators and went with the biggest cam that didn’t loose peak torque. I had a difficult time hooking up the previous sbc, and felt rpm was the answer, and knew more power would be even harder to handle. I have 4.11 gears and a t56 magnum. Car has plenty of torque down low, and revs well to 7500rpm, peak power is almost 7k feels like it has wide power curve rolls on nice even at 2500rpm and at 3500+ rpm it’s explosive. Had to upgrade to autocross tires to make it hook at all, otherwise it would spin the tire at speed, at 55mph it would spin the tire at 3500rpm in 3rd. You can’t beat the big three, heads, cam and compression.

My personal vote is heads cam on the 406, it bbc is heavy, and makes the front end feel funny, imho. The supercharged ls is a tight fit, and expensive!!lol probably 20k plus before your done, and the Muncie will feel outdated. I started out with a 4 speed as well and I had problems with the clutch linkage binding under load, engine was twisting everything up, putting a ratchet strap on the engine helped, but I decided to convert to hydraulic. Long post,sorry