A saw has to be small.

Small engines make less vibration with shorter strokes.

A shorter stroke makes the engine lighter.

The longer a stroke, the more counter balance(weight) and over-all size(weight) an engine needs, even if it is not laying in your hands(weight).

McCulloch knew this when they made their 125 a 58mmX46.6mm affair vs Yamaha making their YZ125 motocross engine a 54mmX54.4mm. Both engines have a buttload of ports and lovely reed valves, but one is made to take advantage of the fact it is strapped to a big motocross frame with a real gear box and intake/exhaust system allowing it to produce good power, while the other is designed to be hand held and not run out of fuel before you are finished with a face cut. One has a big rod and crank, big carb, and big counter balancers. The other, not so much. One is square, the other not. One makes double digit horse power from 5k RPM all the way up to 13K RPM(delivering 35hp in it's modern stock form at 12.5K), the other is the McCulloch.

McCulloch 125 crank(courtesy of BigMac):

Yamaha YZ125 crank:

TL;DR - Weight+Vibes

If you are designing a high torque engine you most likely aren’t designing a lightweight high rpm unit

I.e. a handheld implement.

Great point about shorter strokes helping with vibrations, I had not considered that.

Thanks for the pictures, I had not seen a McCulloch 125 crank, I think we are agreeing that it is overall design that largely dictates an engines performance, and stroke is just one of many puzzle pieces of the picture?

This can be a hard topic to discuss online, if not only for the fact that we are all probably thinking of different scenarios when reading and replying, when I mention high torque engines, I am not really thinking about chainsaw two strokes, in terms of power and torque the reality is they are not that high performance, as pointed out it is just not their primary design goal, which is made obvious every time you handle a two stroke dirt bike cylinder.

Getting back to the original intention of my comments on torque and stroke, a good example is the 462 and 572, some have seen the 462 has a 34mm stoke, the 572 a 39mm stroke and decided on the operating characteristics then and there, can't do that.

The below quote from AnotherSite is one such that just makes too many assumptions and claims hinging on the 5mm stroke difference.

"The MS 462 has a 52mm Bore and 34mm Stroke

The MS 461 has a 52 mm Bore and a 36mm Stroke

The 572xp has a 48mm Bore and a 39mm Stroke

The longer stroke will mean more low end torque especially with heavier components. The 461 has a heavier flywheel than either of the new saws with the other two being very close to the same flywheel weight.

The longer stroke of the 572xp with the new style engine designs that force in outside air the 572xp will be very close in power with a 461 but have a lot of potential ported. It wont be a screamer like a 462 but it will do what a 70cc is supposed to do better."

Joes Dyno has found this not to be the case, and even if it was, which it very well could have been, the reasoning behind it would have still been flawed.

The McCulloch vs Yz125 was an interesting one, lets also compare some contemporary, similarly dimensioned (bore/stroke) two strokes

with completely different performance criteria.

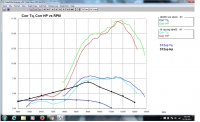

The KTM 65 SXS from a dyno chart (found online) shown further down, this being the factory hot rod version rated at 19.5hp (at 65cc!), and the 572xp, using Joes dyno results.

And I am not at all trying to be negative to the 572xp with this comparison, it just had the closest bore/stroke dimensions of those listed here.

KTM 65 SXS

bore and stroke 45.0 x 40.8 mm,

64.9cc,

17.4hp @ 11,700 rpm,

7.9ftlb @ 9,800rpm

Husqvarna 572xp

bore and stroke 48.0 x 39.0 mm,

70.6cc,

6.70hp @ 9,500 rpm,

3.8ftlb @ 7800rpm

Considering drive train losses reducing the dyno figure, this dirtbike engine is putting out 8.5ftlb!, same as the ported 3120 "practice saw" with 60x42mm bore and stroke.

KTM Crank Below, basically the same stroke as an ms660 or 2100, though a little more sturdy looking.

572 crank below, looks like they wanted the volume/compression benefits of a circle crank, but didn't want the weight or need the strength, so added crank stuffers.

Below a KTM 65 sx cylinder, check out those transfers!

KTM dyno 65 SXS dyno chart, 572xp roughly overlaid.

Ok, so I am

not at all suggesting this could be a saw engine, it would take a large amount of airflow to cool it for one, I am just highlighting a few things, how much is theoreticality left on the table in terms of torque output (though the bike engine greatly benefits from a tuned pipe compared to OPE), that generally high horsepower also equals high torque (you just pay the price of power delivery being less than optimal) and that a modern saws torque output is not decided by stroke or crank and flywheel weight.