NZsaws

Super OPE Member

- Local time

- 6:13 AM

- User ID

- 25753

- Joined

- Dec 18, 2022

- Messages

- 81

- Reaction score

- 400

- Location

- New Zealand

Gidday Max

It's a two piece but has the pawls for a RH start so maybe they were using up some old stock?

Sort of wished I had filled the holes bit too late now.

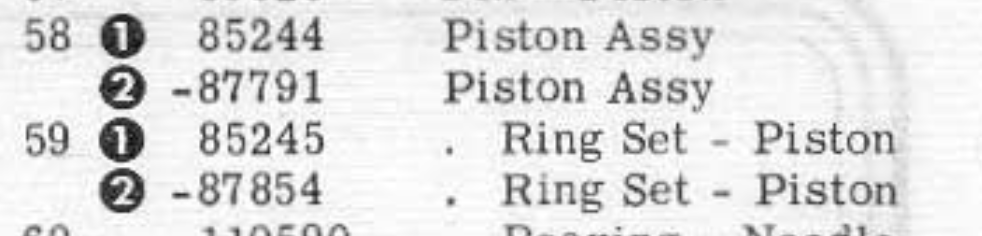

The saw looks hardly used but when I opened it up the ring locators had disappeared. Some dents on squish band but damage minimal. Have put in new ones and have new rings.

It's a two piece but has the pawls for a RH start so maybe they were using up some old stock?

Sort of wished I had filled the holes bit too late now.

The saw looks hardly used but when I opened it up the ring locators had disappeared. Some dents on squish band but damage minimal. Have put in new ones and have new rings.