Merkava_4

Well-Known OPE Member

- Local time

- 6:29 PM

- User ID

- 6626

- Joined

- Jul 7, 2018

- Messages

- 157

- Reaction score

- 136

- Location

- Clovis, California

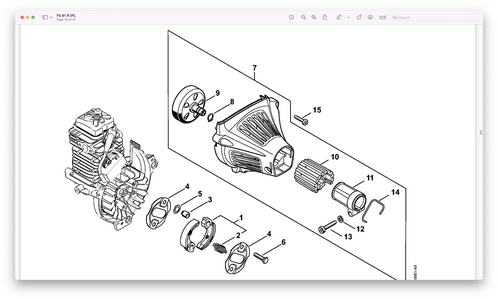

STIHL FS 91 R

Yesterday while cutting a customer's grass in the backyard, the trimmer head all of a sudden stopped turning and I could hear this ZING sound coming from the clutch drum. My first thought was I either fried the clutch or broke a clutch spring. Come to find out after getting the trimmer home and upon disassembly, the driveshaft that goes into the clutch drum was rounded off. It's supposed to be a perfect 5mm square. The other end of the driveshaft that goes into the gearbox was perfectly fine.

My suspicion of why the driveshaft got rounded off was due to running the trimmer line too far out. The blade on the guard will cut the line somewhere between five and six inches. At times I've had the trimmer line out as far as eight inches especially on low load situations such as edging a sidewalk.

It's running the line too far out while cutting wet tall grass is what I suspect rounded off the driveshaft end.

You may wonder why I took the guard off. The short answer is I feel more coordinated with the trimmer with the guard off, especially while edging.

If all I had to do it cut grass and never have to edge, I'd probably have the guard on.

One thing for sure is that the guard cuts down on a lot of green splatter that's constantly spraying me.

What I used to have is a little piece of 1/4 inch plastic tubing cut to a length of six inches.

I would slide that tubing over the trimmer line up against the eyelet and cut the portion of line off that extended past the end of the tube.

But I lost that little piece of tubing.

Ace Hardware had a new driveshaft in stock last night. I couldn't believe it.

Lastly, I wonder if a splined driveshaft would've held up better.

Yesterday while cutting a customer's grass in the backyard, the trimmer head all of a sudden stopped turning and I could hear this ZING sound coming from the clutch drum. My first thought was I either fried the clutch or broke a clutch spring. Come to find out after getting the trimmer home and upon disassembly, the driveshaft that goes into the clutch drum was rounded off. It's supposed to be a perfect 5mm square. The other end of the driveshaft that goes into the gearbox was perfectly fine.

My suspicion of why the driveshaft got rounded off was due to running the trimmer line too far out. The blade on the guard will cut the line somewhere between five and six inches. At times I've had the trimmer line out as far as eight inches especially on low load situations such as edging a sidewalk.

It's running the line too far out while cutting wet tall grass is what I suspect rounded off the driveshaft end.

You may wonder why I took the guard off. The short answer is I feel more coordinated with the trimmer with the guard off, especially while edging.

If all I had to do it cut grass and never have to edge, I'd probably have the guard on.

One thing for sure is that the guard cuts down on a lot of green splatter that's constantly spraying me.

What I used to have is a little piece of 1/4 inch plastic tubing cut to a length of six inches.

I would slide that tubing over the trimmer line up against the eyelet and cut the portion of line off that extended past the end of the tube.

But I lost that little piece of tubing.

Ace Hardware had a new driveshaft in stock last night. I couldn't believe it.

Lastly, I wonder if a splined driveshaft would've held up better.