066 redeye

Super OPE Member

- Local time

- 7:56 PM

- User ID

- 3407

- Joined

- Jun 18, 2017

- Messages

- 319

- Reaction score

- 745

- Location

- Tasmania,Australia.

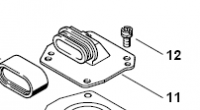

Also should mine have the plastic tag.

Had no tag on it so fitted a metal one.

Chris.

Had no tag on it so fitted a metal one.

Chris.