- Local time

- 4:58 AM

- User ID

- 18248

- Joined

- Aug 14, 2021

- Messages

- 506

- Reaction score

- 2,076

- Location

- NorthCountry

"Off with their heads" or something like that.

I may scrap all the short pieces, but definitely keep the longer ones.

ISO 12.9 grade bolts & cutoff pieces.

View attachment 475217

I don't smith!You could make a Damascus stack with the short pieces.

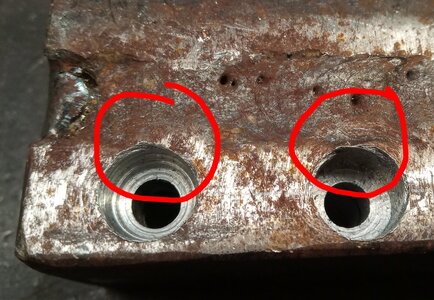

I couldn't get the CR-V Allen wrench cutoff threaded so I tried tempering it.

View attachment 476289

It helped, I got a M10x1.5 thread about 30mm deep into it.

The first 10mm are drilled out to 10.0mm to serve as a pilot hole.

It is a strong firm thread and it only took several tries.

View attachment 476290

View attachment 476291

I may not have used the metallurgy professions/industries correct term, though I believe I did write it properly.I think you meant to say annealed it. Heat it up, hold it for a bit, and then let cool very slowly to remove and hardening.