Squareground3691

Here For The Long Haul!

- Local time

- 9:13 AM

- User ID

- 16376

- Joined

- May 1, 2021

- Messages

- 3,291

- Reaction score

- 15,862

- Location

- New England

Yes , the collets will work for all ur diameter applications,@Squareground3691 and @Wilhelm, thanks so much for the help!

I was leaning towards an ER32 holder and collet set, and it sounds like adding some larger Weldon holders to that would be a good idea.

I was also thinking of adding a precision keyless drill chuck as well, but in Squaregrounds pics it looks like the collets will work for drilling bits as well? The collet set I am looking at is stepped by 1/32", so that would give me a decent range to start.

Thanks again for the helpful advice! I think that I am starting to get a grip on mill tool holding (pun intended).

ER11 & ER16 collets clamp down by 1.0mm from specified clamping OD, though You should stay shy at no more than 0.9mm.

ER32 collets will also clamp down by 1.0mm from spec, and they'll do so firmly.

That been said look into buying collets in 1.0mm steps and You should be able to cover a very wide range of tooling OD.

There are special collets for taps, but the standard ones work just as well.

The tap collets have a square hole in their bottom section, better clamping force and can save on having to length index the tap.

Apologies for the metric references!

At one point we had no ER32 key at work, for a couple months, for 18 mills, hundreds of tool holders.

I began making my own custom ones, they are only missing a lever to be welded on.

Yes , the collets will work for all ur diameter applications,

Here is link to a great free book that you will find interesting: Machine Shop Trade Secrets by James Harvey. You can read it online for free or download it for free in various formats. Did I mention that it's free?

It has lots of tips and tricks about machining, tooling, making things, working faster and more efficiently, and solving problems. It is fairly modern too and includes info on CNC machining.

Carbide is standard fair , if you can afford it depending on the work and materials being machined, HSS is not productive in holding tolerances and finishes , Carbide Inserts are generally used in lathe applications , for turning, boring,threading etc, , Milling is basically the same approach, Solid carbide or inserts , but like I mentioned it’s all about what ur doing and materials being machined that applies to and can afford, HSS can be used if ur not to fussy, and affordable for a wider range of tooling and materials being cut aren’t to hard on HSS tools,Alright...I have more questions. Again, if I am cluttering this thread and need to start a new one, let me know.

I was reading about rotary tables for milling last week. No question there, we're definitely getting one of those!

But, at the risk of opening a can of worms, I do want to ask about HSS vs indexable carbide inserts for cutters. I have read that smaller (hobby) machines don't have the juice to run carbide tips well, but that isn't an issue here. The lathe has a 13" swing and is 40" in length, and the vertical mill has a 10" x 54".

I have also read that, for milling at least, that carbide is worth the money for experienced users, which is a more important consideration. I seriously doubt that "experienced" will apply to anyone using the machines, and so it seems like going with HSS cutters for the mill will get us more tools. I'll be spending more time sharpening, but there seems to be a smaller chance of damaging the work and tools.

Are there any specific milling tools that would be better with carbide inserts if I go with HSS for the majority?

I'm not sure whether the same is true for cutters for the lathe though...are indexable tips the way to go there?

I know that it is a bug (and vague) question, with a lot of possible answers, but I'll take any advice that I can get.

Alright...I have more questions. Again, if I am cluttering this thread and need to start a new one, let me know.

I was reading about rotary tables for milling last week. No question there, we're definitely getting one of those!

But, at the risk of opening a can of worms, I do want to ask about HSS vs indexable carbide inserts for cutters. I have read that smaller (hobby) machines don't have the juice to run carbide tips well, but that isn't an issue here. The lathe has a 13" swing and is 40" in length, and the vertical mill has a 10" x 54".

I have also read that, for milling at least, that carbide is worth the money for experienced users, which is a more important consideration. I seriously doubt that "experienced" will apply to anyone using the machines, and so it seems like going with HSS cutters for the mill will get us more tools. I'll be spending more time sharpening, but there seems to be a smaller chance of damaging the work and tools.

Are there any specific milling tools that would be better with carbide inserts if I go with HSS for the majority?

I'm not sure whether the same is true for cutters for the lathe though...are indexable tips the way to go there?

I know that it is a bug (and vague) question, with a lot of possible answers, but I'll take any advice that I can get.

Carbide is standard fair , if you can afford it depending on the work and materials being machined, HSS is not productive in holding tolerances and finishes , Carbide Inserts are generally used in lathe applications , for turning, boring,threading etc, , Milling is basically the same approach, Solid carbide or inserts , but like I mentioned it’s all about what ur doing and materials being machined that applies to and can afford, HSS can be used if ur not to fussy, and affordable for a wider range of tooling and materials being cut aren’t to hard on HSS tools,

HSS tooling certainly has its place in machining, but Solid-Carbide does nearly everything - better, faster, longer.

A Solid-Carbide drill bit is much more rigid than a identical OD HSS/HSS-Co drill bit.

It will drill into nearly any material without needing a pilot hole, whilst a HSS drill bit can and will wander without one.

I'd say get a supply of both HSS & Solid-Carbide to see what works best for Your application.

When restocking tooling You simply leave out what is not being used.

'Hobby' machines are fine with small, sharp, positive rake, small nose radius inserts like CCMT. They do not run well with any larger, blunt, negative rake, large nose inserts.

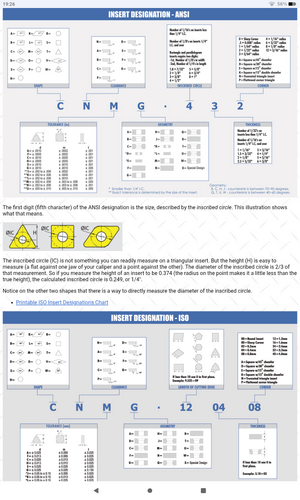

Here is a chart that shows the insert ID system:

Your machines are larger than the small hobby ones, so they should be able to run the bigger, industrial inserts.

Look for bundles of used tooling and job lots of mixed inserts on eBay. You can get a large amount of tooling for little money. And you can cherry-pick the holders and inserts that suit your machines and sell the bigger stuff on.