You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Metalworking Thread

- Thread starter davidwyby

- Start date

Squareground3691

Here For The Long Haul!

- Local time

- 9:47 PM

- User ID

- 16376

- Joined

- May 1, 2021

- Messages

- 3,295

- Reaction score

- 15,866

- Location

- New England

Sadly? , better than Chinnnnnnaaa !!

- Local time

- 3:47 AM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,857

- Reaction score

- 59,045

- Location

- Croatia

- Local time

- 3:47 AM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,857

- Reaction score

- 59,045

- Location

- Croatia

Used to be, hopefully still is - hard to tell with so much stuff being made in China yet getting advertised as made in XYZ.Sadly? , better than Chinnnnnnaaa !!

Al Smith

Here For The Long Haul!

- Local time

- 9:47 PM

- User ID

- 537

- Joined

- Jan 14, 2016

- Messages

- 6,681

- Reaction score

- 14,921

- Location

- North western Ohio

If you cut to the chase you really have no idea where it's made .

Al Smith

Here For The Long Haul!

- Local time

- 9:47 PM

- User ID

- 537

- Joined

- Jan 14, 2016

- Messages

- 6,681

- Reaction score

- 14,921

- Location

- North western Ohio

Out sourcing is world wide on just about everything no matter what it is .I made my living for over 40 years of a 50 year stint working on high speed metal working machinery in the automotive business .I've worked with machine vendors from all over the world .One company ABB from Switzerland now makes robotics in China .That's just one example of many .

- Local time

- 3:47 AM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,857

- Reaction score

- 59,045

- Location

- Croatia

- Local time

- 3:47 AM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,857

- Reaction score

- 59,045

- Location

- Croatia

- Local time

- 6:47 PM

- User ID

- 5156

- Joined

- Jan 24, 2018

- Messages

- 9,667

- Reaction score

- 38,367

- Location

- Extreme Southeast CA

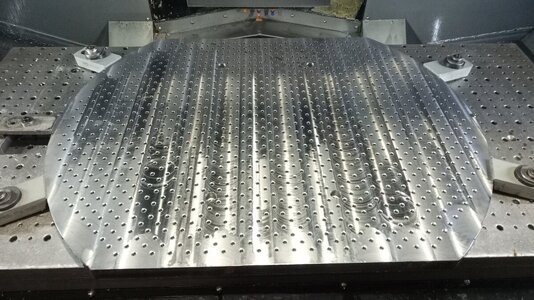

My RH guy built the die assy

- Local time

- 6:47 PM

- User ID

- 5156

- Joined

- Jan 24, 2018

- Messages

- 9,667

- Reaction score

- 38,367

- Location

- Extreme Southeast CA

- Local time

- 3:47 AM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,857

- Reaction score

- 59,045

- Location

- Croatia

- Local time

- 3:47 AM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,857

- Reaction score

- 59,045

- Location

- Croatia

Squareground3691

Here For The Long Haul!

- Local time

- 9:47 PM

- User ID

- 16376

- Joined

- May 1, 2021

- Messages

- 3,295

- Reaction score

- 15,866

- Location

- New England

Squareground3691

Here For The Long Haul!

- Local time

- 9:47 PM

- User ID

- 16376

- Joined

- May 1, 2021

- Messages

- 3,295

- Reaction score

- 15,866

- Location

- New England

- Local time

- 6:47 PM

- User ID

- 5156

- Joined

- Jan 24, 2018

- Messages

- 9,667

- Reaction score

- 38,367

- Location

- Extreme Southeast CA

BlackCoffin

Pinnacle OPE Member

- Local time

- 6:47 PM

- User ID

- 11676

- Joined

- Feb 6, 2020

- Messages

- 421

- Reaction score

- 2,400

- Location

- Washington

Similar threads

- Replies

- 78

- Views

- 9K