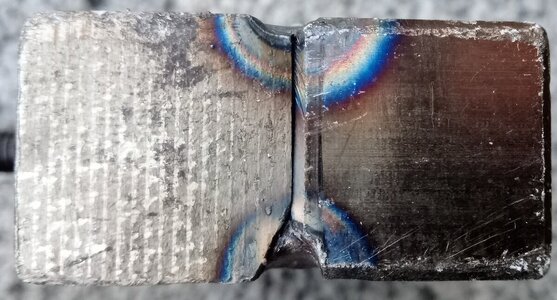

View attachment 423619

So, I found myself needing a small piece of cast iron this week, to repair/rework a hole that was drilled off-center in a bearing housing. We didn't have any stock available, aside from another cast iron blank that had porosity on the finished OD (material issue, so it got scrapped). I chopped a small chunk out of the good side of the part, and then rounded off one end on the belt sander.

Every single lathe in the shop was occupied, so I made the decision to make the entire patch piece in the knee mill.

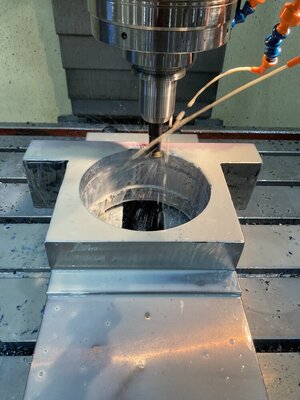

View attachment 423620

Using the mill's quill power feed, a lathe tool in the vise, and the part blank in a collet, I turned the blank to the desired size for threading. I chose 1/4-20 in this instance

View attachment 423622

Ran a sharp die over my cast iron "pin" and then drilled and tapped the bad hole in the part to match my newly created plug. Then, I installed my piece of cast iron threaded rod with red loctite, and milled the top down flush. The new hole was drilled and tapped in the proper location, and the repair is acceptable for what that hole will do.

View attachment 423625

I figured alot of guys would never think to use a mill in this manner, as an improvised lathe, so it seemed worth sharing. It's gotten me out of a bind on a few occasions. Sometimes, you just have to find a way to use what's in front of you.