I like threads like this with trail and error, lots of ideas tossed around. I also like you’re doing what I said F it to with a 70cc class Stihl, the Swedes have more potential for this stuff.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stihl ms 460/660 Hybrid. 469e

- Thread starter NateSaw

- Start date

- Local time

- 10:15 AM

- User ID

- 26310

- Joined

- Mar 13, 2023

- Messages

- 1,033

- Reaction score

- 2,910

- Location

- Maryland, USA

The Echo cs900evl piston saga.

Piston #1:

I should have left well enough alone. It was the control group... Then I turned the skirt struts into toothpicks

Piston #2: What was an excellent idea, turned into a crank vent, and I should've caught it before making it happen... Piston #2 will get an immediately following post with pictures and explanations.

Piston #3: Basically back to where I need to be. The only two differences from #1 being a squish set to 0.020" (instead of 16though cause I needed my head checked), and I left the skirt full circle. I never did give that a chance because I was hung up in weight. Tommorow, piston #3 goes in, and I'll see.

Piston #1:

I should have left well enough alone. It was the control group... Then I turned the skirt struts into toothpicks

Piston #2: What was an excellent idea, turned into a crank vent, and I should've caught it before making it happen... Piston #2 will get an immediately following post with pictures and explanations.

Piston #3: Basically back to where I need to be. The only two differences from #1 being a squish set to 0.020" (instead of 16though cause I needed my head checked), and I left the skirt full circle. I never did give that a chance because I was hung up in weight. Tommorow, piston #3 goes in, and I'll see.

- Local time

- 10:15 AM

- User ID

- 26310

- Joined

- Mar 13, 2023

- Messages

- 1,033

- Reaction score

- 2,910

- Location

- Maryland, USA

Piston # 2.... My big booboo...

@Mastermind, and many if you other pro builders likely knew piston two wouldn't run, because you've likely followed my math and knew that I had to turn my uppers into truck stops.

If you look closely, you'll see that hog is nearly 5/8" tall... Makes sense after knocking around 0.170" off the base. And you've likely seen the shot showing the piston @bdc barely covers 1/3 of the port...

Here's a shot with the ring pushed into the jug, atop the slug, that I locked at bdc... It's hard to see, but zoom in and you can read about 3/8" from top of piston to floor of upper transfer port...

Wellllllll ya theeeee, the problem is that the top of piston #2 became smaller than 0.375"...thoooooo she had a leaky aorta... How proper is it, that piston #2 is poo! Anywho... That's what I fugged up... Beside becoming childlike and forgetting scientific process, I also didn't measure everything. This saw will be a college educations worth....

@Mastermind, and many if you other pro builders likely knew piston two wouldn't run, because you've likely followed my math and knew that I had to turn my uppers into truck stops.

If you look closely, you'll see that hog is nearly 5/8" tall... Makes sense after knocking around 0.170" off the base. And you've likely seen the shot showing the piston @bdc barely covers 1/3 of the port...

Here's a shot with the ring pushed into the jug, atop the slug, that I locked at bdc... It's hard to see, but zoom in and you can read about 3/8" from top of piston to floor of upper transfer port...

Wellllllll ya theeeee, the problem is that the top of piston #2 became smaller than 0.375"...thoooooo she had a leaky aorta... How proper is it, that piston #2 is poo! Anywho... That's what I fugged up... Beside becoming childlike and forgetting scientific process, I also didn't measure everything. This saw will be a college educations worth....

Ketchup

Epoxy member

- Local time

- 8:15 AM

- User ID

- 5594

- Joined

- Mar 12, 2018

- Messages

- 2,518

- Reaction score

- 8,474

- Location

- Colorado

Sounds like you should start a thread. We've got enough members and builders here to supply the data. I bet with as many saws as some see in a year the data could come in quickly. It doesn't take much time to collect it.

We need a standard template for the crankshafts and pistons to keep everything as organized as possible. Sounds like @redline4 might have a lead on the crankshafts template.

I've got a couple different saws torn apart right now that I could collect the crankshaft and piston data on. I was going to do it anyhow just for future reference if needed. Ive been wanting to build a stroker/hybrid out of a smaller saw hence the reason for starting to collect information. I already have all the dimensions for one saw wrote in a notebook.

Crankshaft data base

I was thinking that a data base of crank measurements (I know) would be useful. When I decided to swap a Solo 681 crank into a Dolmar 7900, Randy and I measured and compared cranks (I know). Could really open the door for some cool builds. I’m not asking you to pull out your crank and measure...

- Local time

- 10:15 AM

- User ID

- 26310

- Joined

- Mar 13, 2023

- Messages

- 1,033

- Reaction score

- 2,910

- Location

- Maryland, USA

- Local time

- 10:15 AM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,525

- Reaction score

- 150,437

- Location

- East Jordan, MI

I rarely mess around with stuff like this because sooner or later someone will show up with a pure 1128 and kick your ass with it. That’s just how it goes.

But on the other hand, I kind of wanna see how it runs. Lord knows it won’t be the first time we’ve seen an 066 grenade on video

But on the other hand, I kind of wanna see how it runs. Lord knows it won’t be the first time we’ve seen an 066 grenade on video

- Local time

- 10:15 AM

- User ID

- 26310

- Joined

- Mar 13, 2023

- Messages

- 1,033

- Reaction score

- 2,910

- Location

- Maryland, USA

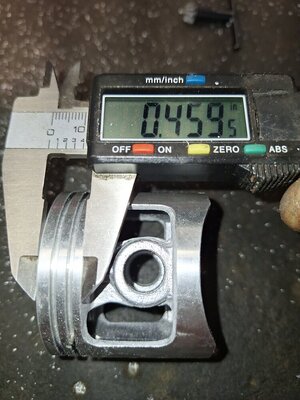

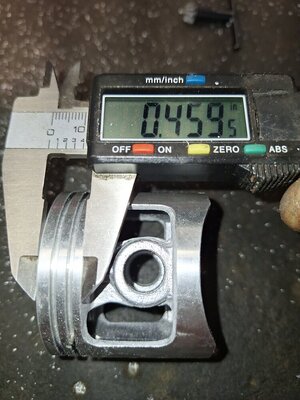

And for anyone wondering how much further I could drop the jug....

I'd say not much more than 0.060". But I was able to pull a 0.035" band cut with this setup. Another 0.005 would make a tight chamber and I doubt that's kill it. However...

If I measure to the second ring... You can see that likely the only sealing is coming from a film of oil... So the jury is still way out on this one... It's very possible I'm dead wrong with my theory that this thing was ever air starved... Even piston 3 might not get it. I'll report back tommorow... I guess I'll video regardless. It'll learn us what not to do... Even if just because we can

I'd say not much more than 0.060". But I was able to pull a 0.035" band cut with this setup. Another 0.005 would make a tight chamber and I doubt that's kill it. However...

If I measure to the second ring... You can see that likely the only sealing is coming from a film of oil... So the jury is still way out on this one... It's very possible I'm dead wrong with my theory that this thing was ever air starved... Even piston 3 might not get it. I'll report back tommorow... I guess I'll video regardless. It'll learn us what not to do... Even if just because we can

- Local time

- 10:15 AM

- User ID

- 26310

- Joined

- Mar 13, 2023

- Messages

- 1,033

- Reaction score

- 2,910

- Location

- Maryland, USA

I knew you'd beat me to it. My grand finale was going to be my humble admission that being able to put all this together, weather it work or not, will NEVER compare to the art that is what you and the fellers do on here Kevin. I don't mind sticking my neck out. My hope would be for you to get your hands on THIS and KICK my ass with itI rarely mess around with stuff like this because sooner or later someone will show up with a pure 1128 and kick your ass with it. That’s just how it goes.

But on the other hand, I kind of wanna see how it runs. Lord knows it won’t be the first time we’ve seen an 066 grenade on video

Why not deck the case?

- Local time

- 8:15 AM

- User ID

- 26178

- Joined

- Feb 23, 2023

- Messages

- 1,808

- Reaction score

- 5,852

- Location

- Montana

@NateSaw I do have a question about the free porting of the upper transfers. Maybe I didn't follow what you said? How is that free port a problem? I ask to learn, plus ask since all open transfer cylinders already have the same (more actually) free port. I was under the impression the open transfers biggest problem is lack of air direction from the lowers to and through the uppers with how it flows the air into the cylinders? More dead heads then flows. Comparing open an open transfer to an closed transfer it's easy to see the lack of air flow direction.

What am I missing? I'm here to learn, of that maybe means asking a stupid question, so be it! Fire away! Others are more than welcome to fire away, let's not limit it to just Nate thumping me! LOL

What am I missing? I'm here to learn, of that maybe means asking a stupid question, so be it! Fire away! Others are more than welcome to fire away, let's not limit it to just Nate thumping me! LOL

- Local time

- 8:15 AM

- User ID

- 26178

- Joined

- Feb 23, 2023

- Messages

- 1,808

- Reaction score

- 5,852

- Location

- Montana

I bookmarked the thread. Thank you! Looks like it's time to bump that thread and get it rolling again.Crankshaft data base

I was thinking that a data base of crank measurements (I know) would be useful. When I decided to swap a Solo 681 crank into a Dolmar 7900, Randy and I measured and compared cranks (I know). Could really open the door for some cool builds. I’m not asking you to pull out your crank and measure...opeforum.com

Have you advanced the ignition?

Ketchup

Epoxy member

- Local time

- 8:15 AM

- User ID

- 5594

- Joined

- Mar 12, 2018

- Messages

- 2,518

- Reaction score

- 8,474

- Location

- Colorado

@NateSaw I do have a question about the free porting of the upper transfers. Maybe I didn't follow what you said? How is that free port a problem? I ask to learn, plus ask since all open transfer cylinders already have the same (more actually) free port. I was under the impression the open transfers biggest problem is lack of air direction from the lowers to and through the uppers with how it flows the air into the cylinders? More dead heads then flows. Comparing open an open transfer to an closed transfer it's easy to see the lack of air flow direction.

What am I missing? I'm here to learn, of that maybe means asking a stupid question, so be it! Fire away! Others are more than welcome to fire away, let's not limit it to just Nate thumping me! LOL

I think you’re right that the transfer upper isn’t freeporting just because it opens above and below the rings at the same time. But the missing ring and raised piston windows allow a pathway from the case out the exhaust, killing case compression.

- Local time

- 9:15 AM

- User ID

- 2584

- Joined

- Feb 4, 2017

- Messages

- 7,036

- Reaction score

- 47,705

- Location

- Winona County, MN

Run piston #1 !!

- Local time

- 10:15 AM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,525

- Reaction score

- 150,437

- Location

- East Jordan, MI

Lollzzzz

- Local time

- 8:15 AM

- User ID

- 26178

- Joined

- Feb 23, 2023

- Messages

- 1,808

- Reaction score

- 5,852

- Location

- Montana

That's the only spot I could really see it hurting. You know it has to be feeding case pressure out the exhaust.I think you’re right that the transfer upper isn’t freeporting just because it opens above and below the rings at the same time. But the missing ring and raised piston windows allow a pathway from the case out the exhaust, killing case compression.

- Local time

- 10:15 AM

- User ID

- 26310

- Joined

- Mar 13, 2023

- Messages

- 1,033

- Reaction score

- 2,910

- Location

- Maryland, USA

Bingo. That's it. And it's a big traffic jam waiting to get off the freeway. Thanks Caleb. I'm not good at explaining.I think you’re right that the transfer upper isn’t freeporting just because it opens above and below the rings at the same time. But the missing ring and raised piston windows allow a pathway from the case out the exhaust, killing case compression.

- Local time

- 10:15 AM

- User ID

- 26310

- Joined

- Mar 13, 2023

- Messages

- 1,033

- Reaction score

- 2,910

- Location

- Maryland, USA

- Local time

- 10:15 AM

- User ID

- 26310

- Joined

- Mar 13, 2023

- Messages

- 1,033

- Reaction score

- 2,910

- Location

- Maryland, USA

Nope.Run piston #1 !!

- Local time

- 10:15 AM

- User ID

- 26310

- Joined

- Mar 13, 2023

- Messages

- 1,033

- Reaction score

- 2,910

- Location

- Maryland, USA

Yes. The usual. 0.077"-0.052"Have you advanced the ignition?