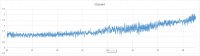

The new dyno has the RPM sensing at 1:1 instead of on the 5:1 reduced shaft and Bill has 16 magnets on there for 16 pulses per revolution. The old one had RPM resolution to the nearest 250 RPMS (it would have been 50 RPMs if 1:1 instead of 5:1 with 6 magnets on old setup). The new one has better than nearest 40 RPM resolution a more than 5:1 improvement.

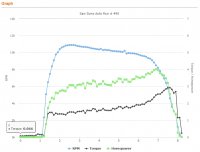

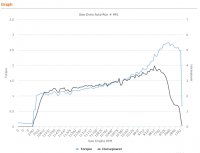

The new dyno pump creates a load you can't get rid of such that my stock 372XP X-torq saw maxes out at 11,000 RPMs or so running the pump with little to no flow restriction by the valve. It translates to a constant torque going in, but since the valve isn't applying a decent load, you get this flatness of the graph for a while at 10000 - 11000 RPM depend on how much you loosen the valve to start your run and then the extreme right-hand side of the graph is where it gets more interesting. I will need to adjust the software to be more picky about where it graphs to avoid the mostly boring stuff up to the extreme right of the graphs below.

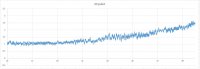

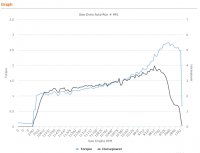

We were trying different filters here -- 10 point through 60 point in increments of 10. 30 point seemed to be plenty to get useful data.

I think the key here is the 372 is showing a rather consistent 4.0 HP or so at 9K RPM or so. Much more consistent than the motorcycle one IMHO.

In the graphs below when you look at peak area it's always 4 HP at around 9K.

I know that's a bit low for a stock 372, I can't explain why it's low we may have something wrong or haven't factored in something. We were fighting daylight to get the runs taken. What I'm happy about is the consistency -- all w/in 0.1 to 0.2 HP of one another instead of much larger changes.

Wondering if the pump is possibly cavitating or if there is some kind of blow by going on.

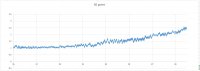

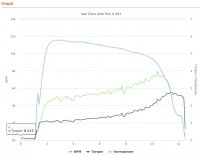

Here are the graphs given the older start/stop strategy which isn't the best for the new setup.

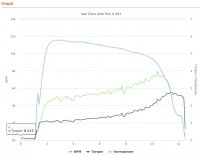

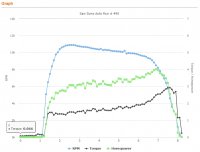

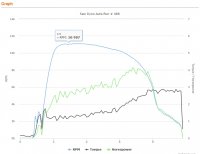

I'm going to include RPM on bottom (which screws the scales on either side for torque and HP) and then the ones with the RPM as an axis and time on the bottom which forces torque and HP to use the same scale and then you can see them cross at 5252 RPM like they should:

Fine resolution on the RPM blue line below. Black torque and Green HP cross at 5252 RPM at the extreme right of the graph which with hydraulic dyno extrreme right of the graph is the most interesting part.

We get the peak HP at 4.0 HP or so again here. Across several runs they are all w/in 0.1 HP of 4.0 on this setup.