You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Saw Dyno

- Thread starter malk315

- Start date

paragonbuilder

Mastermind Approved!

- Local time

- 3:37 PM

- User ID

- 384

- Joined

- Jan 2, 2016

- Messages

- 9,229

- Reaction score

- 33,871

- Location

- Norwich, CT

Jason will treat you right!Cool. I got my eyes open for a good used one. Any advice for me on a particular model? Just a few basic models for Stihl I was looking at. 440, 660, etc?

paragonbuilder

Mastermind Approved!

- Local time

- 3:37 PM

- User ID

- 384

- Joined

- Jan 2, 2016

- Messages

- 9,229

- Reaction score

- 33,871

- Location

- Norwich, CT

Here is the link

ms440

http://opeforum.com/index.php?threads/ms440.2527/

Sent from my iPhone using Tapatalk

ms440

http://opeforum.com/index.php?threads/ms440.2527/

Sent from my iPhone using Tapatalk

mdavlee

Hillbilly grinder

- Local time

- 3:37 PM

- User ID

- 279

- Joined

- Dec 28, 2015

- Messages

- 14,194

- Reaction score

- 64,634

- Location

- TN

Grab the 440 from Jason. It's a slick saw that runs great now.Cool. I got my eyes open for a good used one. Any advice for me on a particular model? Just a few basic models for Stihl I was looking at. 440, 660, etc?

MustangMike

Mastermind Approved!

- Local time

- 3:37 PM

- User ID

- 338

- Joined

- Dec 30, 2015

- Messages

- 11,546

- Reaction score

- 36,440

- Location

- Brewster, NY

I really like my 70 cc Stihls.

But, since you guys were talking classics, anyone interested in a Stihl 08 S??? I picked one up cheap. Not in mint shape, but it seems complete and has compression (have not tried to start it). Even has a B&C.

If anyone is interested in it, let me know.

But, since you guys were talking classics, anyone interested in a Stihl 08 S??? I picked one up cheap. Not in mint shape, but it seems complete and has compression (have not tried to start it). Even has a B&C.

If anyone is interested in it, let me know.

malk315

Running Saws for Therapy

- Local time

- 3:37 PM

- User ID

- 421

- Joined

- Jan 6, 2016

- Messages

- 2,101

- Reaction score

- 10,152

- Location

- Lancaster, MA

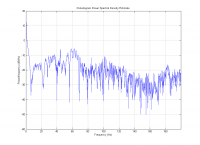

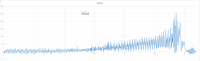

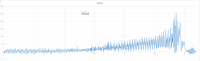

During the Mass mini GTG at my place today was able to collect data every 2.5ms for Torque unfiltered. Below are graphs of unfiltered and then w/ 60 point decimation filter applied. Still a bunch of vibration from the brake rotor, but filtering makes it usable to some extent.

@srcarr52 I'll PM you a link to the raw data -- finally got 3.2 seconds of data every 2.5ms w/o any missing. Some jitter going on, but all of the points are there. Hoping you can possibly come up with the best type of digital filtering we could do given the rate we're collecting data (400hz).

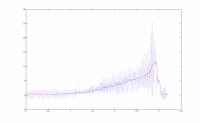

And the filtered version:

@srcarr52 I'll PM you a link to the raw data -- finally got 3.2 seconds of data every 2.5ms w/o any missing. Some jitter going on, but all of the points are there. Hoping you can possibly come up with the best type of digital filtering we could do given the rate we're collecting data (400hz).

And the filtered version:

- Local time

- 3:37 PM

- User ID

- 522

- Joined

- Jan 12, 2016

- Messages

- 4,196

- Reaction score

- 27,500

- Location

- Iowa City

malk315

Running Saws for Therapy

- Local time

- 3:37 PM

- User ID

- 421

- Joined

- Jan 6, 2016

- Messages

- 2,101

- Reaction score

- 10,152

- Location

- Lancaster, MA

The 4 hz low pass looks similar to the 60 point decimation filter I've used with my 2.5 ms update rate (equivalent in time period to the 30 point decimation filter applied to 5 ms sampling).

So since the frequencies are rather variable we can't really target a particular frequency (correct me if I'm wrong there) which is a bummer.

Bill now has a way to read the load cell to look at the vibrations live on a scope style graph I put together on the raspberry Pi setup he lent me. It reads the load cell at 2.5 ms intervals and plots them close to real time. He's going to experiment with truing up a rotor or two along with a few other things to try and get mechanical improvement. After that it may be time to switch to a hydraulic setup. Still plenty to try.

Thanks Shaun.

So since the frequencies are rather variable we can't really target a particular frequency (correct me if I'm wrong there) which is a bummer.

Bill now has a way to read the load cell to look at the vibrations live on a scope style graph I put together on the raspberry Pi setup he lent me. It reads the load cell at 2.5 ms intervals and plots them close to real time. He's going to experiment with truing up a rotor or two along with a few other things to try and get mechanical improvement. After that it may be time to switch to a hydraulic setup. Still plenty to try.

Thanks Shaun.

malk315

Running Saws for Therapy

- Local time

- 3:37 PM

- User ID

- 421

- Joined

- Jan 6, 2016

- Messages

- 2,101

- Reaction score

- 10,152

- Location

- Lancaster, MA

Wanted to post an update here so you guys don't think the project has died off -- work is still happening on a hydraulic setup. I've seen a couple of updates from Bill on the PM thread we've had and it will be way cool to give that setup a try when it's ready.

I also pointed Chad to this thread after I contacted him via PM as I had found some threads on AS where he was looking at off the shelf electronics for his dyno setup.

I thought perhaps if he wanted to try my electronics with his setup it could help me make things further generic with the software and excuse to build another setup or two.

He said he was going to check all of this out but haven't heard back from him. It's been a while (several weeks).

That's the latest.

I also pointed Chad to this thread after I contacted him via PM as I had found some threads on AS where he was looking at off the shelf electronics for his dyno setup.

I thought perhaps if he wanted to try my electronics with his setup it could help me make things further generic with the software and excuse to build another setup or two.

He said he was going to check all of this out but haven't heard back from him. It's been a while (several weeks).

That's the latest.

MustangMike

Mastermind Approved!

- Local time

- 3:37 PM

- User ID

- 338

- Joined

- Dec 30, 2015

- Messages

- 11,546

- Reaction score

- 36,440

- Location

- Brewster, NY

Eric, I did some informal timed cuts with my saws in some 18.5" Oak, and the results are very consistent with the dyno results using the method I concocted for determining the HP (the average of a minimum of 7 consecutive data points) and using the best obtained dyno run for that saw. My 2 strongest saws, which each had a dyno run of over 8 Hp were both able to produce a cut time of just over 12 seconds.

Last edited:

malk315

Running Saws for Therapy

- Local time

- 3:37 PM

- User ID

- 421

- Joined

- Jan 6, 2016

- Messages

- 2,101

- Reaction score

- 10,152

- Location

- Lancaster, MA

Eric, I did some informal timed cuts with my saw in some 18.5" Oak, and the results are very consistent with the dyno results using the method I concocted for determining the HP (the average of a minimum of 7 consecutive data points) and using the best obtained dyno run for that saw. My 2 strongest saws, which each had a dyno run of over 8 Hp were both able to produce a cut time of just over 12 seconds.

That is awesome Mike -- I think we did pretty well considering the pulses we would get from the brake and such. With the next one it looks like the RPMs will be coming off a shaft turning at saw crank speed which will likely mean an improvement in resolution (we did nearest 250 RPMs with the 6 magnets and 5X reduction, this one has no reduction). Hoping the pump being driven by the saw into the load cell will be smoother -- there has got to be some improvement there.

Hoping to mess with that 044 today.

Deets066

AKA Deetsey

- Local time

- 3:37 PM

- User ID

- 290

- Joined

- Dec 28, 2015

- Messages

- 15,443

- Reaction score

- 73,596

- Location

- Illinois

I'd really like to see Chad become a member here, he was a good dude with a lot of cool inputWanted to post an update here so you guys don't think the project has died off -- work is still happening on a hydraulic setup. I've seen a couple of updates from Bill on the PM thread we've had and it will be way cool to give that setup a try when it's ready.

I also pointed Chad to this thread after I contacted him via PM as I had found some threads on AS where he was looking at off the shelf electronics for his dyno setup.

I thought perhaps if he wanted to try my electronics with his setup it could help me make things further generic with the software and excuse to build another setup or two.

He said he was going to check all of this out but haven't heard back from him. It's been a while (several weeks).

That's the latest.

Deets066

AKA Deetsey

- Local time

- 3:37 PM

- User ID

- 290

- Joined

- Dec 28, 2015

- Messages

- 15,443

- Reaction score

- 73,596

- Location

- Illinois

When you gunna dyno some more saws? I got a hybrid here I wouldn't mind sending ya.That is awesome Mike -- I think we did pretty well considering the pulses we would get from the brake and such. With the next one it looks like the RPMs will be coming off a shaft turning at saw crank speed which will likely mean an improvement in resolution (we did nearest 250 RPMs with the 6 magnets and 5X reduction, this one has no reduction). Hoping the pump being driven by the saw into the load cell will be smoother -- there has got to be some improvement there.

Hoping to mess with that 044 today.

malk315

Running Saws for Therapy

- Local time

- 3:37 PM

- User ID

- 421

- Joined

- Jan 6, 2016

- Messages

- 2,101

- Reaction score

- 10,152

- Location

- Lancaster, MA

Hey Keith -- once we prove out the pump setup you guys will be the first to know!

I'm hoping one meeting w/ Bill to test and then only a day or two to make software mods I'm sure will be necessary with the new setup.

I'd be happy to do another Mass mini dyno GTG or see if Dan is up for meeting at his place. Dan has a great setup for it.

I'm hoping one meeting w/ Bill to test and then only a day or two to make software mods I'm sure will be necessary with the new setup.

I'd be happy to do another Mass mini dyno GTG or see if Dan is up for meeting at his place. Dan has a great setup for it.

MustangMike

Mastermind Approved!

- Local time

- 3:37 PM

- User ID

- 338

- Joined

- Dec 30, 2015

- Messages

- 11,546

- Reaction score

- 36,440

- Location

- Brewster, NY

What are you hiding from us Jason???