You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mcculloch sp125/101b kart saw build thread

- Thread starter Bigmac

- Start date

- Local time

- 12:33 PM

- User ID

- 714

- Joined

- Jan 28, 2016

- Messages

- 4,130

- Reaction score

- 29,578

- Location

- Dike, Iowa

Bigmac

Mastermind Approved!

- Local time

- 10:33 AM

- User ID

- 5937

- Joined

- Apr 19, 2018

- Messages

- 5,769

- Reaction score

- 40,637

- Location

- Oregon

That may be an 880 boot, they are smaller and oval shaped on one side.The 088 boot seems to be to be somewhat smaller I.D. than the original.

View attachment 241513

That one was on an SP105 when I got it, I was able to replace it with an original and kept this as a reminder.

Mark

Here is a pic of all three, mac 125, homelite 750 and 084/088

084, the ring stretches it out to the same as the 750

Homelite 750 with 088 ring

Homelite 750 with 088 ring

Mac 125

and the 088 ring on top of the 125 boot for reference

and the 088 ring on top of the 125 boot for reference

the 125 boot is 21.5mm and the 750 and 084 are almost 27mm 26.5 safely the wb3 is 25.2mm so it’s a good match, the wb37 is a little too big at 28mm

Bigmac

Mastermind Approved!

- Local time

- 10:33 AM

- User ID

- 5937

- Joined

- Apr 19, 2018

- Messages

- 5,769

- Reaction score

- 40,637

- Location

- Oregon

Got the carb mounted, I think I am going to try some nutserts to mount the carb. I moved the carb up a small amount from version 1, the manifold is going to be a little different too, going to make the base thicker. Carb fits better in the box. I need to find a source for the larger barbed 90° fittings. I want to Powdercoat this one once it all done. going to try this on a modified cp block first and if it works out it will stay, if not it’s getting a kart motor! Lol

Bigmac

Mastermind Approved!

- Local time

- 10:33 AM

- User ID

- 5937

- Joined

- Apr 19, 2018

- Messages

- 5,769

- Reaction score

- 40,637

- Location

- Oregon

So I roll the dice on eBay on a cheap 101 cylinder, I figured for $41 it wasn’t too big a risk., As it turns out it was a 50 over a block and it had been ported, which the seller had said. Did some measuring comparing to a stock 101 AA block I had, Two of the transfer ports were raised and the rest were stock. So I figured I’d give some thing I’ve been rolling around in my head for a while I’ll try. I’ve been wanting to epoxy down the transfer reports on a 101 to under 130°, stock is around 133ish. I would like to get 128-186 instead of the stock 133/186. Based on the numbers I think it should bump torque up quite a bit

- Local time

- 10:33 AM

- User ID

- 232

- Joined

- Dec 24, 2015

- Messages

- 9,734

- Reaction score

- 67,027

- Location

- Coastal Oregon

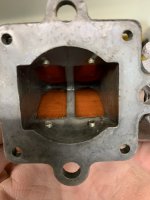

Also epoxyed up the reed cage, there is a big dead air spot, I think it will help throttle response and idle, View attachment 241930

It'll be interesting to see what you come up with on this. The kart guys have done a lot with epoxying blocks to change port timing. One karter was playing around in the

late 60's with one of the nine-port blocks and completely epoxied the nine-port intake shut, and was able to make a lot more power with the engine. He sent his photos

and drawings of the design to McCulloch and that's part of what led to the modern Super Series engines.

Bigmac

Mastermind Approved!

- Local time

- 10:33 AM

- User ID

- 5937

- Joined

- Apr 19, 2018

- Messages

- 5,769

- Reaction score

- 40,637

- Location

- Oregon

That’s awesome! Ya once I port timed the stock blocks I realized how aggressive the porting was stock. I also believe it’s because that it’s because of the round ports are not 100% effective so they kept lifting them to make them work, I am thinking a square-ish port that’s lower will still make the same peak power but have more under peak. But I could be wrong too. Worse case I can lift them back. I am also going to extend the port dividers to the intake manifold too. The other interesting find was how small Bottom transfers are at the top of the ports are really small compared to the intake side, I can get in there and open them up some to match the intake side better, they are really unbalanced stock. It’s going to be interesting, I was lucky that the exhaust was stock on this blockIt'll be interesting to see what you come up with on this. The kart guys have done a lot with epoxying blocks to change port timing. One karter was playing around in the

late 60's with one of the nine-port blocks and completely epoxied the nine-port intake shut, and was able to make a lot more power with the engine. He sent his photos

and drawings of the design to McCulloch and that's part of what led to the modern Super Series engines.

Last edited:

- Local time

- 10:33 AM

- User ID

- 232

- Joined

- Dec 24, 2015

- Messages

- 9,734

- Reaction score

- 67,027

- Location

- Coastal Oregon

Very nice so far, Mr. N. This is gonna be a great project.

- Local time

- 10:33 AM

- User ID

- 232

- Joined

- Dec 24, 2015

- Messages

- 9,734

- Reaction score

- 67,027

- Location

- Coastal Oregon

I'm pretty excited about this action - a .010" over 101AA motor that's going into a saw for a member here. The AA's use the 1/2" wrist pin and rod from the factory.

You can retrofit them with the 9/16" wrist pin pistons if you want, if you have the matching rod or an SP saw piston and rod, again if you have the matching set. I'm not porting it per se',

but will lightly work the ports over just smoothing everything out.

This is gonna be one good runner.

You can retrofit them with the 9/16" wrist pin pistons if you want, if you have the matching rod or an SP saw piston and rod, again if you have the matching set. I'm not porting it per se',

but will lightly work the ports over just smoothing everything out.

This is gonna be one good runner.

- Local time

- 10:33 AM

- User ID

- 193

- Joined

- Dec 24, 2015

- Messages

- 4,574

- Reaction score

- 17,732

- Location

- Oregon

Wow!! That is a beauty!!I'm pretty excited about this action - a .010" over 101AA motor that's going into a saw for a member here. The AA's use the 1/2" wrist pin and rod from the factory.

You can retrofit them with the 9/16" wrist pin pistons if you want, if you have the matching rod or an SP saw piston and rod, again if you have the matching set. I'm not porting it per se',

but will lightly work the ports over just smoothing everything out.

This is gonna be one good runner.

You sure have a vast knowledge on these saws!! Always a pleasure to learn some new details.

- Local time

- 10:33 AM

- User ID

- 232

- Joined

- Dec 24, 2015

- Messages

- 9,734

- Reaction score

- 67,027

- Location

- Coastal Oregon

BonScott46

Pinnacle OPE Member

- Local time

- 7:33 PM

- User ID

- 1571

- Joined

- Jul 20, 2016

- Messages

- 1,065

- Reaction score

- 3,636

- Location

- Sweden

Gorgeous!I'm pretty excited about this action - a .010" over 101AA motor that's going into a saw for a member here. The AA's use the 1/2" wrist pin and rod from the factory.

You can retrofit them with the 9/16" wrist pin pistons if you want, if you have the matching rod or an SP saw piston and rod, again if you have the matching set. I'm not porting it per se',

but will lightly work the ports over just smoothing everything out.

This is gonna be one good runner.

- Local time

- 10:33 AM

- User ID

- 232

- Joined

- Dec 24, 2015

- Messages

- 9,734

- Reaction score

- 67,027

- Location

- Coastal Oregon

These pictures are mainly for @Definitive Dave , who started a discussion on making replacement pistons for some of the Mac motors.

First up: An SP-125 piston mounted on rod, next to an Mc-101 Piston (9/16" wrist pin) on the early 9/16" wrist pin rod. You can see there's a significant difference in the crown

height on the Mc-101 piston because it used a longer rod. Even though the two set ups both used 9/16" wrist pins, they're entirely different. You can use either set up in a 101 kart

or 125 saw motor as long as you have the matching rods for the pistons. The crankshafts are the same stroke and the rod journal is the same width and diameter.

Next up: 9/16" Mc-101 wrist pin (top) next to an SP-125 9/16" wrist pin (bottom):

First up: An SP-125 piston mounted on rod, next to an Mc-101 Piston (9/16" wrist pin) on the early 9/16" wrist pin rod. You can see there's a significant difference in the crown

height on the Mc-101 piston because it used a longer rod. Even though the two set ups both used 9/16" wrist pins, they're entirely different. You can use either set up in a 101 kart

or 125 saw motor as long as you have the matching rods for the pistons. The crankshafts are the same stroke and the rod journal is the same width and diameter.

Next up: 9/16" Mc-101 wrist pin (top) next to an SP-125 9/16" wrist pin (bottom):

- Local time

- 10:33 AM

- User ID

- 232

- Joined

- Dec 24, 2015

- Messages

- 9,734

- Reaction score

- 67,027

- Location

- Coastal Oregon

I'd like to get @Bigmac and @Lee H involved in the discussion for replacement pistons. I'm thinking that if Dave were to have just a stock replacement + simply oversizes made

for the SP-125 piston, that might be best, since there's a lot of those motors out there and there would be a good market for them.

Next up, back side of the SP-125 piston/rod next to the back side of the Mc-101 piston/rod:

This picture shows a 1/2" wrist pin 101A piston next to a dismounted Mc-101 piston for the 9/16" wrist pin. Again, much difference in crown height is noticeable, because the 9/16"

wrist pin rods were longer.

for the SP-125 piston, that might be best, since there's a lot of those motors out there and there would be a good market for them.

Next up, back side of the SP-125 piston/rod next to the back side of the Mc-101 piston/rod:

This picture shows a 1/2" wrist pin 101A piston next to a dismounted Mc-101 piston for the 9/16" wrist pin. Again, much difference in crown height is noticeable, because the 9/16"

wrist pin rods were longer.

Last edited:

- Local time

- 10:33 AM

- User ID

- 232

- Joined

- Dec 24, 2015

- Messages

- 9,734

- Reaction score

- 67,027

- Location

- Coastal Oregon

This pictures shows the 9/16" wrist pin rod next to the 1/2" wrist pin rod. The 9/16" wrist pin rod is noticeably longer. Some of the early, early 797s

I believe also came with the 9/16" wrist pin pistons and rods.

This pictures shows an SP-125 rod next to the Mc-101 9/16" wrist pin rod. They're completely different.

I believe also came with the 9/16" wrist pin pistons and rods.

This pictures shows an SP-125 rod next to the Mc-101 9/16" wrist pin rod. They're completely different.

- Local time

- 10:33 AM

- User ID

- 232

- Joined

- Dec 24, 2015

- Messages

- 9,734

- Reaction score

- 67,027

- Location

- Coastal Oregon