Cerberus

Cerberus the aardvark, not the hell-hound!!

- Local time

- 9:02 AM

- User ID

- 11523

- Joined

- Jan 20, 2020

- Messages

- 292

- Reaction score

- 121

- Location

- Florida (tampa area)

You could buy a pop up piston for it if you're looking for more compression.

https://www.ebay.com/itm/1849476079...fvIHgiKTHLRkxeMHiMUNq_pQKAxQATtQaAlOPEALw_wcB

First I was like "OMG I how fast can Amazon get me one of these? 2nd ring *and* a 'riser' top on the piston to create more compression*, sign me up!" but then see @Nutball 's advisements and am now confused/uncertain.... Is Golf a brand or a type? And is 'brick' here meaning heavy/weight, IE heavier piston is slower, or 'brick' like 'bricked-engine' meaning maybe it has propensity to slam-into // heat-fuse to the top of the cylinder?

Would never have guessed there was legit 3rd-party performance parts for the 590, any others you guys know-of? Will be googling heavily now, obviously, but had thought such things as "good aftermarket performance-pistons" were a small niche focused on the 44*/66* crowd exclusively, apparently not

Can you swap pistons without taking apart the case? If I had to take the case apart, it'd be a deal-breaker (for now!)

2nd-ring seems to be a big highlight, I'd always been under the impression that the 2nd rings are "nice, but not too critical", would love to hear specifics IE maybe there's more compression because-of the 2nd ring? If so, are we talking 0.5psi or 5psi? Also, Re compression, is it true that the seal-off of a decomp-valve boosts compression? Is this "in theory" or actually >1%?

Would certainly get a better piston if I knew it'd net me 15psi or take my squish from 30 to 20thousandths, and I did not have to split the case in-half to replace it

I'd thought I did 20% of OEM port-height on the exhaust-ceiling (and around 15% enlargement, relative to OEM-height, of the intake, by grinding its floor) however am now a bit uncertain if I did go as-far as I'd thought....will have a timing-wheel on it today (going to have to McGuyver something ugly because the chuck will NOT come off this old, corded, generic Black&Decker etry-level drill, the chuck is keyed and I can 'back spin' it but it just spins the engine and there's no 'lock' to stop the engine from spinning.... Going to need to come up with something else, shouldn't be very hard to make, calibrate/verify and put to use, so I can come back here w/ better #'s because I'm itching to get into Round-2 I have all the bits and everything am only holding-back til I finish "the plan"!Raising the exhaust 20% of the total height seems like a lot, how much did you raise it?

This blows my mind I mean I read the entire Exhaust porting thread here, have heard & learned a bunch on it and...this is the 1st time I've heard of hitting the exhaust-floor!On the 600 and 620 I did I went the opposite direction and lowered the exhaust because I wanted it to have good torque to run a 24" bar. I think they are both at 109.

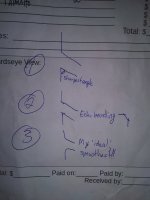

Would you mind explaining the logic behind "lower exhaust-floor for torque", and any other "related considerations" (IE what do you change/do to work with a lower exhaust-floor?), any enlightenment would be greatly appreciated, have dozens and dozens of hours of youtubes & reading, including 2 reads of the Exhaust Porting megathread here, and was utterly unaware of the concept of exhaust-floor timing changes until your post here! I mean, hitting the exhaust floor itself, I honestly cannot tell why the goal is anything-but "flare that thing out as-far-as-possible with the confines of the cylinder's aluminum body", for instance here's a crude sketch to show what I mean, Black ink is "OEM cylinder and muffler", and Red ink is material that'd be removed (note: pic has the muffler on as it was drawn for showing the muffler//outlet-flange port-matching that is necessary on this platform)

[Green is gas/air/internal-volume!]

Sorry so crude but hopefully illustrates my point, in fact I'm GG over to the exhaust-megathread to ask there since "it belongs" but I'm having trouble understanding why, subsequent to choosing your inside-facing window's dimensions, from there to the exhaust port's exit-flange, all I can think is "you should dog it out as much-as-possible" (water obscures the top-most 'grinding' in my picture but that line was to show how you can still make a huge reduction of material starting from the OEM port-position you simply sacrifice some flare (maybe....unsure how-thin you can go...Honestly I can't see why you wouldn't want to get the outer-perimeter ("Outer exhaust-port flange perimeter") to be both:

- Circular (since circles flow best and, hey, it's easiest to port-match to the muff

- as wide as the cylinder's material allows... NOT saying this about the port-window on the inside-face of the piston, but as it flares-out to the outer-exhasust-port-flange I can't see why you wouldn't wanna get paper-thin (well, close to it!) since I'd think more volume here = better, as a rule, for example flare all sides like this (only to a circle or as much of a circle as the OEM shape allows you to achieve, at least!)

Be back with timing #'s today or tomorrow, have tons of new tungsten bits so I can do it right, am blown away how well they work, anyway am eager to finish my "blueprints" so I can rip it off & get (back-to!) grinding ;D Sadly that chuck is NOT coming off my old Black&Decker entry-level, keyed-chuck corded drill, so frustrating but it just spins the engine backwards and there's no 'lock-out' to stop it so yeah that chuck isn't going anywhere, am just gonna use a "ghetto interacing" I mean it's just a disc I have to get flat, can check it @ tdc&bdc to ensure proper 'sync' before use but don't expect any fight doing this!!