- Local time

- 7:41 AM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,525

- Reaction score

- 150,436

- Location

- East Jordan, MI

100% agreeTruth

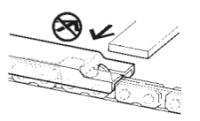

And I have found that most "flat plate" filing guides hold the file a bit too high for semi chisel

This type

100% agreeTruth

And I have found that most "flat plate" filing guides hold the file a bit too high for semi chisel

This type

Thanks, CR888...I think it is to the right...I'm not keen on having to file those fins..

Sharpening is a skill, that also requires some practice/experience and a little bit of knowledge. Lots of ways to do it (files, grinders, rotary / Dremel tools, different types of file guides, etc.). Everybody needs to find something that works for them. Try what feels comfortable to you.Here's a few more pics I took this evening that might or might not help in this discussion/diagnosis...As well as the cheap gauge I used. I picked up a "progressive" Husky gauge tonight and I'm going to give that a try...

They have smaller ones on the Husky file guides, but you still won’t be able to use with safety rails.Picked this up last night, but yeah, like you said Philbert, guess it won't work on these chains....Oh well, good for my bigger saws anyway....wonder if they make a smaller one...

you need more hook.

(Actually, that is '91' stamped on it; but 4mm / 5/32" is the right size file).Wonky, at this point all I can say is that the chain has the number 16 stamped on it....

Which is another reason I hate the *s-word..It’s hard to get hook on semi chisel cutters. Gotta keep the file down a hair lower to get it to bite on its own, which will also sacrifice a little durability unfortunately

That is one ef'd up looking cat..Good evening,,, I was just having a reread. Through this thread !

This may be silly but I have to ask it.. because if I don’t, we’re going down a long street to nowhere. Please Read to the end and you will understand.

So do you know how to find out the pitch of you chain.. it’s in that pdf link

Philbert said it looks like a typical 3\8 lopro.. in your pic you show a .325 file gauge.

Yes with some file gauges you can use them for any pitch of chain..as with some other gauges there not able to be used on different pitches.

#####

However, the size of files is very important with the pitch of chain,, and some manufacturers say different to others for the same pitch.

######

So if your using the wrong size file for the chain your never going to get it to cut properly..

So what is your chain pitch and the size of the file..

I can tell you I made the mistake of thinking I could use a 4mm file holder with a 5.5mm file... till it cut like crap and couldn’t understand why. Then the light bulb came on

Only after reading through that pdf..

Btw. I can’t tell from the pic for sure if that chain is a .325 or 3/8 lopro, and some saws can be changed and peeps do change them..

Anyway if you are using the correct file for the chain, then please ignore this silly question