Thanks, Terry,

I really appreciated that story about your day with Jerry Branch. It reminds me that sometimes it isn't so much what you take out, but what you put in. The story of the air horn reminds me of another story; a concept in cars that makes no real sense, but makes the owners feel better about performance.

People often think bigger brakes are better for their cars, especially in regard to stopping power, but bigger brakes do not make you stop any faster. Stopping power is a function of the contact between the tires and the road, and the pads and your rotors. Bigger brakes allow you to fit larger rotors, which can hold more thermal mass before the pad starts to over-heat and slip. Therefore, larger brakes allow more frequent use between cool-down periods before experiencing brake fade. This would be useful in a track situation where you build maximum speed and are hitting the brakes hard in every corner as try to shed speed, but not so much in a daily driver. In a daily driver, larger brakes just add more unsprung weight, and aren't necessary to increase stopping power. However, many people spend extra money for the big brake kits when it isn't necessary or useful. Anyway, it just goes to show that what many intuit as somehow better can actually be wrong.

I was thinking about this question: is the amount of air an engine consumes dictated by the bore x stroke of the piston/cylinder, or by the carburetor's venturi? If the amount of air is dictated by the piston-cylinder, then the venturi simply controls the air-speed. If the air-speed is decreased, for a given jet size, would less fuel be pulled into the airstream? If the air-speed is increased, for a given jet size, would more fuel be pulled into the airstream? While some might think that the smaller venturi is a choke point, reducing airflow and therefore fuel, it might be that a smaller venturi would have greater air speed and could pull more fuel into the airstream.

I wanted to clarify my interpretation of what I think may be happening with the Zama carb modification.

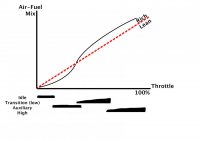

I made up this chart, which may be wrong, but tries to explain what I'm thinking.

On the X-axis you have throttle position, but you can also think of this as RPMs. On the Y-axis you have air-fuel mix. The red dotted line represents the "ideal" stoichiometric mixture ratio, which may be between 14.1 to 15:1. Along the bottom of the graph are four jets that may be found in the Zama carb which contribute to fuel flow in different parts of the throttle range. In the low part of the thottle range (or at low RPM), the fuel is delivered by the idle jet. Although we can play with the choke to reduce airflow and richen the mixture, or adjust the throttle screw to allow more air, I'm showing that due to the fixed jet size, the fuel mixture is considered 'lean'.

At about 1/4 throttle the auxiliary jet opens up and contributes fuel, but because of our dear EPA , the jet is actually too small to supply very much fuel for the amount of air, and the mixture is still considered lean. The transition, or low-speed, jet has as ramp up in opening to add fuel (as I tried to show by a triangle shape), which is determined by the pop-off pressure of the spring. Changing the POP will change the shape of the ramp. At this point, we can also play with the low-speed needle to add more fuel to richen up the mixture or lean it out.

In the higher throttle position of the graph the fuel mix is rich, but is tunable by the high-speed jet. Most people will want to tune the saw to be close to the stoichiometric ratio for optimum efficiency.

If my image is correct, it should indicate that the low and high speed adjustment needles really affect the upper half of the throttle range, and therefore higher RPM values. While we have control over the air-fuel mixture here, we have little control over the mix at partial throttle and therefore lower RPMs. While cookie-cutting saws often sit at a specific RPM range, a work saw would benefit from having more control in the full throttle/RPM range. But come to think of it, a race saw cutting cants or cookies would benefit from having a faster spool-up time. So having more control over the full throttle-range would be beneficial.

If we drill the low jet, the auxiliary jet, and the mixing chamber jet, we can add more fuel at this lower throttle/RPM range.