You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's on your bench?

- Thread starter Adirondackstihl

- Start date

mdavlee

Hillbilly grinder

- Local time

- 3:32 AM

- User ID

- 279

- Joined

- Dec 28, 2015

- Messages

- 14,194

- Reaction score

- 64,634

- Location

- TN

Best to use OEM with seal for an 088 mill saw, or are the aftermarket ones just as good..

Almost toasted a new 088 p&c, had a very small, slow leak on the clutch side, probably from getting too hot.

Any of you Miller's run a saw wide open for a whole tank of gas when milling??

15 minutes in cut, full throttle, try to maintain 7200-7500 rpm by putting gentle pressure on the mill.

???

Yes. All the time if the log is long enough. I use a husky a lot more for that with the outboard clutch. They don't keep as much heat in the case. I usually run 8500-10k in the cut with square filed chain.

redoakneck

Pinnacle OPE Member

- Local time

- 3:32 AM

- User ID

- 620

- Joined

- Jan 20, 2016

- Messages

- 878

- Reaction score

- 1,995

- Location

- Ohio326

Yes. All the time if the log is long enough. I use a husky a lot more for that with the outboard clutch. They don't keep as much heat in the case. I usually run 8500-10k in the cut with square filed chain.

I'm trying to figure out a way for the saw to run cooler, engine cover off or on make a difference??

Sharp chains for sure.

Cold water poured on the bar between cuts ??

Take clutch cover off, or put some frogzskin on it??

Ice on the bar???

mdavlee

Hillbilly grinder

- Local time

- 3:32 AM

- User ID

- 279

- Joined

- Dec 28, 2015

- Messages

- 14,194

- Reaction score

- 64,634

- Location

- TN

More rpm in the cut will force more air across the fins. Try to keep it up around 9k. The cover is what keeps the air from the flywheel going by the fins. The clutch starts to slip probably at 5-6k so that could be adding heat to it if there's some slippage. Clutch cover off might let more heat escape the drum.

exSW

'Cause Thomas is a poopyhead

- Local time

- 3:32 AM

- User ID

- 109

- Joined

- Dec 23, 2015

- Messages

- 5,072

- Reaction score

- 16,701

- Location

- United States

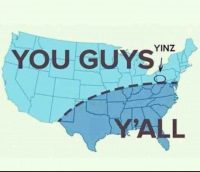

That does it. I'm going to find that rope that binds Allegheny County to the red of us and cut that biatch. Let you'ns float down the Ohio.This forum accepts all sexual orientations..its ok.

PA Dan

FYD

- Local time

- 3:32 AM

- User ID

- 306

- Joined

- Dec 28, 2015

- Messages

- 7,362

- Reaction score

- 36,683

- Location

- White Oak PA

Hey Ross he's in Westmoreland County!That does it. I'm going to find that rope that binds Allegheny County to the red of us and cut that biatch. Let you'ns float down the Ohio.

sawmikaze

Mastermind Approved!

- Local time

- 3:32 AM

- User ID

- 625

- Joined

- Jan 20, 2016

- Messages

- 9,948

- Reaction score

- 54,139

- Location

- steeltown

PA Dan

FYD

- Local time

- 3:32 AM

- User ID

- 306

- Joined

- Dec 28, 2015

- Messages

- 7,362

- Reaction score

- 36,683

- Location

- White Oak PA

Ya me too![emoji41]Ya but only a beer piss away..same same.

PA Dan

FYD

- Local time

- 3:32 AM

- User ID

- 306

- Joined

- Dec 28, 2015

- Messages

- 7,362

- Reaction score

- 36,683

- Location

- White Oak PA

Nice![emoji481] [emoji481]

exSW

'Cause Thomas is a poopyhead

- Local time

- 3:32 AM

- User ID

- 109

- Joined

- Dec 23, 2015

- Messages

- 5,072

- Reaction score

- 16,701

- Location

- United States

Well,at least its not FayettenamHey Ross he's in Westmoreland County!

PA Dan

FYD

- Local time

- 3:32 AM

- User ID

- 306

- Joined

- Dec 28, 2015

- Messages

- 7,362

- Reaction score

- 36,683

- Location

- White Oak PA

Like a whole other planet down there!Fayette county is a trip..dead bodys..peachins...it goes down there.

- Local time

- 2:32 AM

- User ID

- 1377

- Joined

- Jun 5, 2016

- Messages

- 33,999

- Reaction score

- 215,380

- Location

- Northwoods of Wisconsin

MS361 with bad clutch, couple of weed whizzers, carburetor from a Kohler and part of a 3 hp B&S. On whizzer I had parts for out the door, Kohler back to running excellent, and to heck with that saw for now, time for a ride on the Harley.

The fuel system on this old Stihl was baked to a crisp. literally everything hard as a rock.

Nikkki carburetor rebuilt to stop engine from surging

Fitting a new piston by knurling to an old Briggs for a project of my own. Cleaned up cylinder with a 3M contraption on a drill, worked out good.

The fuel system on this old Stihl was baked to a crisp. literally everything hard as a rock.

Nikkki carburetor rebuilt to stop engine from surging

Fitting a new piston by knurling to an old Briggs for a project of my own. Cleaned up cylinder with a 3M contraption on a drill, worked out good.

sawmikaze

Mastermind Approved!

- Local time

- 3:32 AM

- User ID

- 625

- Joined

- Jan 20, 2016

- Messages

- 9,948

- Reaction score

- 54,139

- Location

- steeltown

Like a whole other planet down there!

It really is..ive seen more *s-word there rather than the city..you can buy stolen cars for dirt cheap...or anything else for that matter...

Brewz

Free Range Human in a Tax Farm

- Local time

- 7:32 PM

- User ID

- 550

- Joined

- Jan 16, 2016

- Messages

- 4,217

- Reaction score

- 14,326

- Location

- Hunter Valley - Australia

a. palmer jr.

Pinnacle OPE Member

- Local time

- 3:32 AM

- User ID

- 1389

- Joined

- Jun 10, 2016

- Messages

- 601

- Reaction score

- 1,357

- Location

- Southern Indiana

Bought a couple of parts saws last Saturday, an Echo 351VL and a Stihl 034. I have the Echo running after much aggravation taking the carb off it and putting a new kit in it. Not sure why Echo can't make things easy..anyway, the Stihl needs a top end so I ordered an 036 piston and cylinder for it, might give it a little more oomph. Hopefully I'll have it running in a couple of weeks..

jake wells

no longer here

couple of weeks!!!!??? your fast haha.Bought a couple of parts saws last Saturday, an Echo 351VL and a Stihl 034. I have the Echo running after much aggravation taking the carb off it and putting a new kit in it. Not sure why Echo can't make things easy..anyway, the Stihl needs a top end so I ordered an 036 piston and cylinder for it, might give it a little more oomph. Hopefully I'll have it running in a couple of weeks..

Brewz

Free Range Human in a Tax Farm

- Local time

- 7:32 PM

- User ID

- 550

- Joined

- Jan 16, 2016

- Messages

- 4,217

- Reaction score

- 14,326

- Location

- Hunter Valley - Australia

Similar threads

- Replies

- 5

- Views

- 378