legdelimber

Pinnacle OPE Member

- Local time

- 12:05 PM

- User ID

- 8391

- Joined

- Jan 14, 2019

- Messages

- 767

- Reaction score

- 1,927

- Location

- N.C.

My friend with that missing finger was in the salvage business.

I've spent a few days pulling nails and screws plus driving ceramic wire tubes out etc, from reclaimed wood.

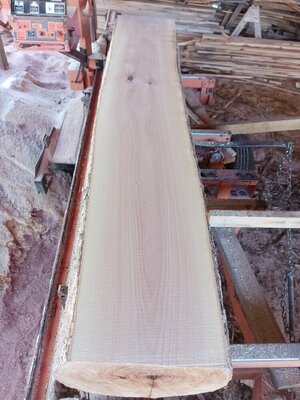

Some of the beams were heart pine and 18" thick. Gorgeous wood!

The guy who re-cut it had an electric leaf blower (metal impeller type) mounted on his wood-mizer band-mill.

He routed it to blow into a truck bed. Not much bucket time needed!

The mill rack was set about 3ft high. He was fairly tall guy.

Good working height for the tractor with front end loader.

Seemed like keeping a good set to the teeth helped with keeping the blade from wandering so much.

Feed rate too though of course.

Water feed always on the blade. don't recall if it ever had any sort of slippery stuff in it, as that might affect color of wood or staining and painting etc.

the sawyer also grew cane and had made a press for squeezing it to make molasses.

Over those years, I got to meet some pretty interesting folks through the salvage dude.

I've spent a few days pulling nails and screws plus driving ceramic wire tubes out etc, from reclaimed wood.

Some of the beams were heart pine and 18" thick. Gorgeous wood!

The guy who re-cut it had an electric leaf blower (metal impeller type) mounted on his wood-mizer band-mill.

He routed it to blow into a truck bed. Not much bucket time needed!

The mill rack was set about 3ft high. He was fairly tall guy.

Good working height for the tractor with front end loader.

Seemed like keeping a good set to the teeth helped with keeping the blade from wandering so much.

Feed rate too though of course.

Water feed always on the blade. don't recall if it ever had any sort of slippery stuff in it, as that might affect color of wood or staining and painting etc.

the sawyer also grew cane and had made a press for squeezing it to make molasses.

Over those years, I got to meet some pretty interesting folks through the salvage dude.