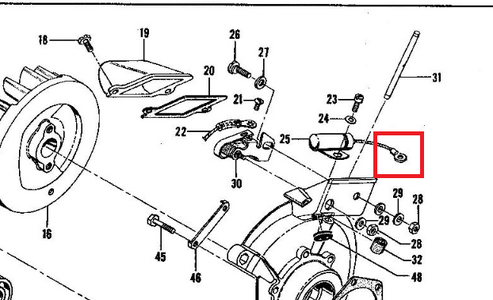

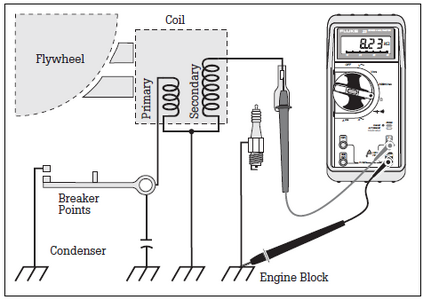

Hello, may I ask how I would go about pressure testing. Do I seal at manifold in air box and exhaust. If this holds then check off and if not do I remove tank and repeat with bare intake . Next if fails I remove clutch and flywheel ( soap and water).

I will also get a supply of seats as Mark stated the swelling makes the Flat back unpredictable from day to day.

I do want to run with the flat back but am hedging my options, picked up two tillotson’s. The 63F is in great shape and the 87DT is rough but will get cleaned up. Also aware that a 090 carb can be used as well.

The sdc seems to be a little out of reach.