czar800

Mastermind Approved!

- Local time

- 8:15 AM

- User ID

- 533

- Joined

- Jan 14, 2016

- Messages

- 7,167

- Reaction score

- 37,480

- Location

- Ellwood City

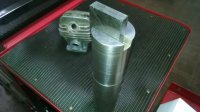

.025 of the keyway. Most recommend .020, but I've gone as much as .030 and got more rpm. I find .025 to be a good balance.

Mandrel angles sounds interesting. You're gonna cut the piston dome off, correct

Is he making you angled sanding mandrels as well?

Thanks Al .025 it is.

He cut the piston flat, but left a little just like your pic.

I never asked about sanding mandrels..