STOVE

Well-Known OPE Member

- Local time

- 3:38 AM

- User ID

- 34149

- Joined

- Aug 29, 2025

- Messages

- 174

- Reaction score

- 467

- Location

- Eastern NC

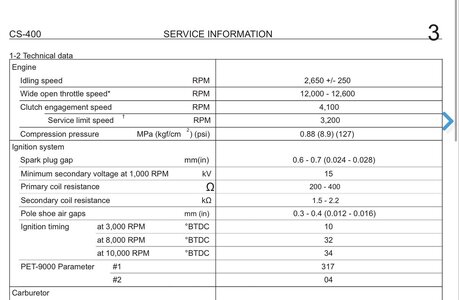

I read lots of posts about timing advances on 50cc saws and larger.

Do people advance the timing on smaller 30-40cc saws? Does it provide a noticeable enough difference to be worth the effort?

Do people advance the timing on smaller 30-40cc saws? Does it provide a noticeable enough difference to be worth the effort?