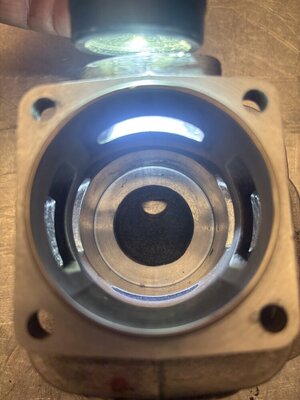

this is my pic too. if you mess up there are others out there everywhere. the 266 had a nice tight chamber. bgd, widen the exhaust and open up the muffler will help a good bit. the intake I would lower if the duration seemed low, you have to check it first.

common newb mistakes...

Don't hog out the lowers! just because you can doesn't mean you should

Port shape symmetry and gentle radius, chamfer the ports and then check for a smooth edge with your finger. use a piece of sand paper on your finger tip to smooth rough edges.

clean the cylinder with a petroleum based solvent. use an old toothbrush and scrub it like crazy. when you are done clean it again.

Once its dry spray a degreaser on a white paper towel. Purple power, zep purple, LA awesome, simple green. wipe the cylinder wall down. if there is any discoloration on the paper towel. clean it some more.

when done rinse with water, dry and coat with oil either a spray on oil or take mixing oil, motor oil, and coat inside the cylinder.

don't get greedy first go round.