Cerberus

Cerberus the aardvark, not the hell-hound!!

- Local time

- 2:17 PM

- User ID

- 11523

- Joined

- Jan 20, 2020

- Messages

- 292

- Reaction score

- 121

- Location

- Florida (tampa area)

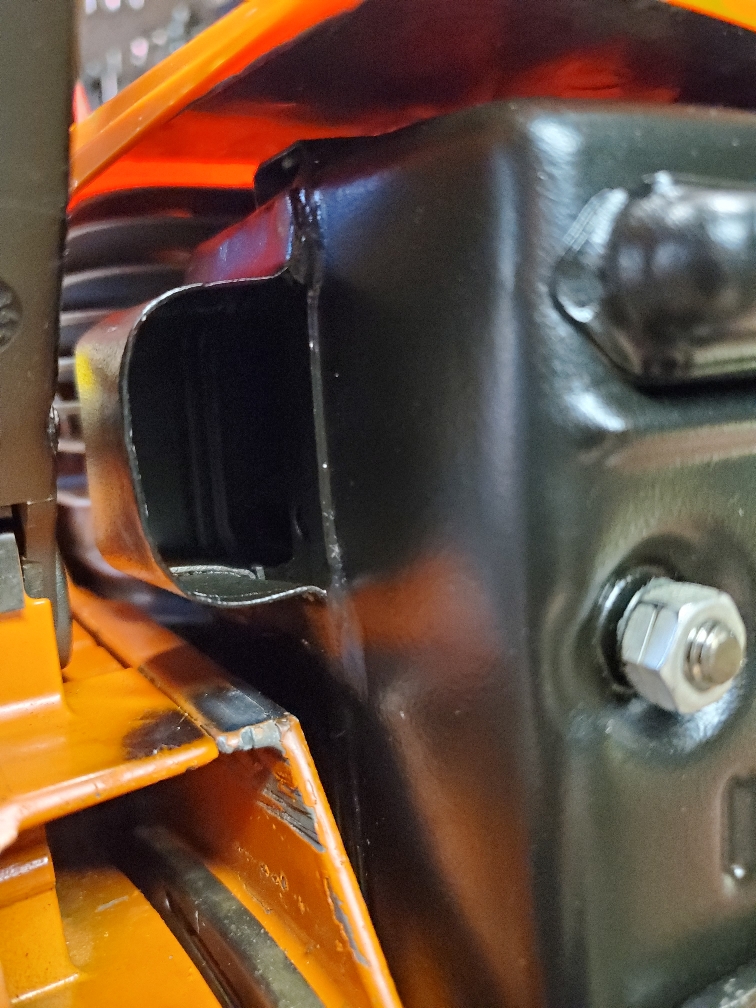

Anyone play around w/ Dominant Saw's AMAZING idea of a "header" type washer they call a "Grunt Gasket"? Photo of an 880's:

880 internals, basically the 'beta version' of how I wanted my 660 to be....wish the "pickup"/entrance for the gas were more obscured (even a baffle plate in front of it, just so it's not taking high-velocity "bloom" that's rolling-back that'd otherwise have had to bang-off the flange first), would realllly love knowing if this muff's tunnel has choke-points besides its final exit!

I was re-reading/watching everything I've found on pipes("expansion chambers") and, while our regular muffler-cans are not pipes and therefore won't benefit us via sonic/acoustic properties, there's still another important function (for all 2-stroke mufflers/exhausts) which is not allowing (excessive)charge-escape when piston is coming off BDC and 'spill out' occurs, therefore I love designs like say a 660 wherein the primary outlet forces the exhaust pulse to bloom-out against front-cover, roll back and pass (forcefully!) the exhaust-flange, pushing-in charge spill-out, as piston's going up compression-stroke for "another round")

ANYWAYS upon re-reading Jennings' section on exp.chambers especially the earlier parts of the chamber IE inlet/divergence cone, I was so stoked seeing this "Grunt Gasket", will be buying & grinding steel blocks if I have to so I can make one for each of my 660's....will of course port-match this to my already-flared exhaust ports, but THAT is an area I'm interested in "theory-thoughts" on! Specifically:

- "divergence cone" angles are low like sub-10deg, and while unimportant to us I think it belies the point of "they're too-steep"....a point further belied by Jennings' reference to trumpet-shaping as the likely ideal, and his anecdotes how some companies are using multi-angle "entry-pipes" to the divergence cone (and multi-angle divergence cones, say 6deg divergence for the 1st two-thirds and then 8deg for the last third before opening-into the true expansion chamber which, to us, would be the body of our muffler)

- The moto-racing companies moved to tighter exhaust ports, but the 084 to 880 shows Stihl enlarging the divergence of the exhaust port (ie steeper angles/more megaphone'd) -- I'm betting this is because the exhasut port is effectively port-and-divergence cone, for our type of no-pipe 2-strokes!

Would love thoughts, also if anyone's got an 880 muffler & ruler, and would be so kind as to take some photos, I'd be forever grateful!! Had been going-over how to perfect the OEM 660 muff-box and was basically intent upon making it so the box was sealed except for a 1" pipe that began around the spot where the OEM exit is, on the inside of the box, and exited outside the box after a few inches of pipe --- Then I luckily saw the MS-880 muffler and truly LOL'd because Stihl totally perfected and "built-in" the exact mechanism I wanted, now - if I cannot McGuyver/fab one onto a 660 - I at least can have a perfect example of what I want to take to a welder (if anyone's got an 880 muff, I'd be very eager to know if there's a 2nd "choke-point", obviously all OEM muffs have exits & chokes that are lower than optimal, for EPA, anyway the 880's muff looks awesome & seems the sole choke is that dime-sized primary muffler exit, if there's more choke-points I'd be eager to know!)

Outta curiousity, does it seem most saws do get at least 10%ish? And almost no saw beats 15 or 17%? That seems to be the range I see, though I always take (most of these types) of #'s w/ a big grain of salt. The 2511 seems to get a legit >15%, implying it choked the saw in a way that the user can un-do (I'm not wrong in presuming that it's the EPA that makes Stihl under-size the exhaust exit-ports, am I?)

I know this 32% must be some inside joke but am curious the highest you've ever seen, or the highest muff mod + timing advance gains you've ever seen (basically "no porting" gains)

BUT you almost need to because you gotta access the baffle-wall that separates the front&rear halves of the 590 muffler.... I simply did my work and then patched-over the entire top, and put about 60%-exhaust-flange-area exit (made of a pair of rectangles) on the upper-front cover, the way the baffle-wall is configured means this position is the "hardest shot" for the gas, my intent was high throughput through the can with maximal pressure at the flange "post exhausst pulsing" here's a photo:

I know many may look at those 2 rectangular exit-holes and think "that's not enough" but EVERYTHING I've seen (and read) has shown that you wanna err too-small WAY before you ever err too-large (power drops-off very quick when too-large, but being 10% too-small isn't a big deal...think of how powerful so many OEM's are even when choked-up!)

(Re 590's, will say that I'd been loving my 355t for a while when I got the 590 and then 2511, the 355t muff is the easiest muffler to work on for its size, the 590 & 2511t both require real surgery which leads most to "throw out the baby with the bathwater" and simply "bypass", IE take a drill bit and just bore a hole somewhere that 'short circuits' the proper activity of a performance muffler....sure it'll still "cool better" and certainly piss-rev higher than stock ;P )

880 internals, basically the 'beta version' of how I wanted my 660 to be....wish the "pickup"/entrance for the gas were more obscured (even a baffle plate in front of it, just so it's not taking high-velocity "bloom" that's rolling-back that'd otherwise have had to bang-off the flange first), would realllly love knowing if this muff's tunnel has choke-points besides its final exit!

I was re-reading/watching everything I've found on pipes("expansion chambers") and, while our regular muffler-cans are not pipes and therefore won't benefit us via sonic/acoustic properties, there's still another important function (for all 2-stroke mufflers/exhausts) which is not allowing (excessive)charge-escape when piston is coming off BDC and 'spill out' occurs, therefore I love designs like say a 660 wherein the primary outlet forces the exhaust pulse to bloom-out against front-cover, roll back and pass (forcefully!) the exhaust-flange, pushing-in charge spill-out, as piston's going up compression-stroke for "another round")

ANYWAYS upon re-reading Jennings' section on exp.chambers especially the earlier parts of the chamber IE inlet/divergence cone, I was so stoked seeing this "Grunt Gasket", will be buying & grinding steel blocks if I have to so I can make one for each of my 660's....will of course port-match this to my already-flared exhaust ports, but THAT is an area I'm interested in "theory-thoughts" on! Specifically:

- "divergence cone" angles are low like sub-10deg, and while unimportant to us I think it belies the point of "they're too-steep"....a point further belied by Jennings' reference to trumpet-shaping as the likely ideal, and his anecdotes how some companies are using multi-angle "entry-pipes" to the divergence cone (and multi-angle divergence cones, say 6deg divergence for the 1st two-thirds and then 8deg for the last third before opening-into the true expansion chamber which, to us, would be the body of our muffler)

- The moto-racing companies moved to tighter exhaust ports, but the 084 to 880 shows Stihl enlarging the divergence of the exhaust port (ie steeper angles/more megaphone'd) -- I'm betting this is because the exhasut port is effectively port-and-divergence cone, for our type of no-pipe 2-strokes!

Would love thoughts, also if anyone's got an 880 muffler & ruler, and would be so kind as to take some photos, I'd be forever grateful!! Had been going-over how to perfect the OEM 660 muff-box and was basically intent upon making it so the box was sealed except for a 1" pipe that began around the spot where the OEM exit is, on the inside of the box, and exited outside the box after a few inches of pipe --- Then I luckily saw the MS-880 muffler and truly LOL'd because Stihl totally perfected and "built-in" the exact mechanism I wanted, now - if I cannot McGuyver/fab one onto a 660 - I at least can have a perfect example of what I want to take to a welder (if anyone's got an 880 muff, I'd be very eager to know if there's a 2nd "choke-point", obviously all OEM muffs have exits & chokes that are lower than optimal, for EPA, anyway the 880's muff looks awesome & seems the sole choke is that dime-sized primary muffler exit, if there's more choke-points I'd be eager to know!)

I've found DP covers, IF the exits' total surface is the same and they're placed similarly, simply change sound (not louden it), in a good way too (for instance I'd take a pair of 1/2" square exits, side-by-side or an inch apart from each other, before a single 1x1/2" exit even though identical throughput and (I'm postulating) near identical volume, but changed 'note'/sound (noted this on my 590 which I'll elaborate below as someone specifically mentions it)@RI Chevy MS460

I wrap the PTO side opening on a lot of saws now. There's enough extra meat on @Red97 deflectors to supply what's needed.

Same power and less noise than a DP cover.

View attachment 64018 View attachment 64019 View attachment 64020 View attachment 64021 View attachment 64022

ROFL!!Yes Pat.

I only got a 31.8976689% gain with my last muff mod. Had to throw it in the recycle bin and start all over.

Outta curiousity, does it seem most saws do get at least 10%ish? And almost no saw beats 15 or 17%? That seems to be the range I see, though I always take (most of these types) of #'s w/ a big grain of salt. The 2511 seems to get a legit >15%, implying it choked the saw in a way that the user can un-do (I'm not wrong in presuming that it's the EPA that makes Stihl under-size the exhaust exit-ports, am I?)

I know this 32% must be some inside joke but am curious the highest you've ever seen, or the highest muff mod + timing advance gains you've ever seen (basically "no porting" gains)

I'd done same, was my 1st saw to try porting and was copying "tinman" from youtube (mistake, was in real-time so he hadn't botched that one yet-- not trying to put him down he seems a great guy but tbh i cannot recall last time I watched a vid of his)I made a serious painful mistake drilling a 3/8 hole in the tube of a 590 instant regret it's seems as loud as a v8 with just headers lolView attachment 64055

BUT you almost need to because you gotta access the baffle-wall that separates the front&rear halves of the 590 muffler.... I simply did my work and then patched-over the entire top, and put about 60%-exhaust-flange-area exit (made of a pair of rectangles) on the upper-front cover, the way the baffle-wall is configured means this position is the "hardest shot" for the gas, my intent was high throughput through the can with maximal pressure at the flange "post exhausst pulsing" here's a photo:

I know many may look at those 2 rectangular exit-holes and think "that's not enough" but EVERYTHING I've seen (and read) has shown that you wanna err too-small WAY before you ever err too-large (power drops-off very quick when too-large, but being 10% too-small isn't a big deal...think of how powerful so many OEM's are even when choked-up!)

(Re 590's, will say that I'd been loving my 355t for a while when I got the 590 and then 2511, the 355t muff is the easiest muffler to work on for its size, the 590 & 2511t both require real surgery which leads most to "throw out the baby with the bathwater" and simply "bypass", IE take a drill bit and just bore a hole somewhere that 'short circuits' the proper activity of a performance muffler....sure it'll still "cool better" and certainly piss-rev higher than stock ;P )