I'll have to look at it and decide how I want to mount it

The way the 410 is you can mount it flat to the wall if you want. No need for a stand.

I'll have to look at it and decide how I want to mount it

What size are those mounting holes? I want to get the hardware

5/16" seems to work on the ones I have, but I have seen differences between some similar grinders. If you wait until you get the grinder, you can judge both the diameter and length better.5/16 or 3/8 will work, used 3/8 on mine through the bottom..

Thanks!Nice job Philbert!!!

The 'T'-nuts (with hex bolts and washers) hold the grinder to the mounting board.I would like to petition the court to change the name of your "T" nuts to " J" nuts . . .

I was looking at yer wrong set of nutsThanks!

The 'T'-nuts (with hex bolts and washers) hold the grinder to the mounting board.

The 'J'-bolts (with wing nuts and washers) clamp the mounted grinder and angled wooden cleat to the ladder rungs - makes it height adjustable, and lets me use almost any step ladder without drilling.

Philbert

Not sure how comfortable I am with that . . . .I was looking at yer wrong set of nuts

This grinder is gonna require a learning curve....any tips[emoji1]

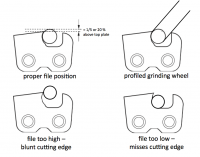

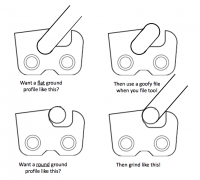

This is a frequent point of discussion, and it's up to you! I lower the wheel until the rounded profile touches the cutter the same way that a file would. This lets me grind in the shop, and file in the field for touch up sharpening. "Grind as you file: File as you grind".How deep do you go just until the wheel meets the side plate?

That's why the safety glasses and guards are important! Exploding wheels get exciting.I destroyed the 3/16 it sounded like a .22...Not sure why it happened . . . .