walcen

Walt

- Local time

- 1:28 AM

- User ID

- 25912

- Joined

- Jan 10, 2023

- Messages

- 23

- Reaction score

- 28

- Location

- Niddrie Melbourne Australia

Hi folks, This is my first post on this forum and having read through a few threads I think I'm in the right place.

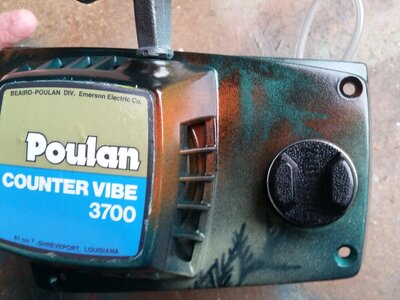

I was given an old one owner home use only poulan 3700 with low comp, 80 psi if that. a complete strip down revealed that the chrome bore and piston are in very good condition however the ring gap is 100 thou, yep you heard right 2.5mm. I'm happy to post pics of my little adventure if any one is interested but I can't find piston rings. there are two thin ring roughly 24 thou.

Any help would be great, thanks in advance and kindest regards,

Walt

I was given an old one owner home use only poulan 3700 with low comp, 80 psi if that. a complete strip down revealed that the chrome bore and piston are in very good condition however the ring gap is 100 thou, yep you heard right 2.5mm. I'm happy to post pics of my little adventure if any one is interested but I can't find piston rings. there are two thin ring roughly 24 thou.

Any help would be great, thanks in advance and kindest regards,

Walt

Last edited: