You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Piston wash patterns

- Thread starter drf256

- Start date

Terry Syd

Pinnacle OPE Member

- Local time

- 1:01 PM

- User ID

- 575

- Joined

- Jan 18, 2016

- Messages

- 1,589

- Reaction score

- 5,987

- Location

- Comboyne, NSW Australia

When I modded my 450 Husky I ran into the overheating piston issue. I did multiple mods to get it to breathe better and it did. It went from a power peak at about 8,000 rpm to 12,000+ rpm.

The piston looked like yours, not just the carbon, but also the top of the piston above the ring touching the cylinder. My engine was getting close to having a heat seizure.

Then the penny dropped. The more power I was making was not only making the engine run hotter, but it was ALSO SUCKING MORE AIR OFF THE FLYWHEEL that could have been keeping the engine cooler. I blocked off the entrance from the flywheel area (air injection system) to the air box using silicon sealer. I then cut a couple of holes in the back of the air box to pull in cool air.

The engine temperature dropped immediately. The plug was now running a proper chocolate brown and the top of the piston was no longer touching the cylinder.

A two-stroke can loose as much as 20% of its power between a cold engine and a hot engine. So, I also gained a bit more power in the mod.

The piston looked like yours, not just the carbon, but also the top of the piston above the ring touching the cylinder. My engine was getting close to having a heat seizure.

Then the penny dropped. The more power I was making was not only making the engine run hotter, but it was ALSO SUCKING MORE AIR OFF THE FLYWHEEL that could have been keeping the engine cooler. I blocked off the entrance from the flywheel area (air injection system) to the air box using silicon sealer. I then cut a couple of holes in the back of the air box to pull in cool air.

The engine temperature dropped immediately. The plug was now running a proper chocolate brown and the top of the piston was no longer touching the cylinder.

A two-stroke can loose as much as 20% of its power between a cold engine and a hot engine. So, I also gained a bit more power in the mod.

- Local time

- 9:01 PM

- User ID

- 21

- Joined

- Dec 4, 2015

- Messages

- 5,336

- Reaction score

- 28,488

- Location

- In a meeting

I've defeated the air injection "system" on every saw of mine that had it.When I modded my 450 Husky I ran into the overheating piston issue. I did multiple mods to get it to breathe better and it did. It went from a power peak at about 8,000 rpm to 12,000+ rpm.

The piston looked like yours, not just the carbon, but also the top of the piston above the ring touching the cylinder. My engine was getting close to having a heat seizure.

Then the penny dropped. The more power I was making was not only making the engine run hotter, but it was ALSO SUCKING MORE AIR OFF THE FLYWHEEL that could have been keeping the engine cooler. I blocked off the entrance from the flywheel area (air injection system) to the air box using silicon sealer. I then cut a couple of holes in the back of the air box to pull in cool air.

The engine temperature dropped immediately. The plug was now running a proper chocolate brown and the top of the piston was no longer touching the cylinder.

A two-stroke can loose as much as 20% of its power between a cold engine and a hot engine. So, I also gained a bit more power in the mod.

No regerts !!!

Terry Syd

Pinnacle OPE Member

- Local time

- 1:01 PM

- User ID

- 575

- Joined

- Jan 18, 2016

- Messages

- 1,589

- Reaction score

- 5,987

- Location

- Comboyne, NSW Australia

I've defeated the air injection "system" on every saw of mine that had it.

No regerts !!!

Yeah, a lot of guys in Oz do that to keep the filter cleaner. The 'air injection; system may work well in Swedish woods of clean, green wood where it deals with wood CHIPS, but here in Oz, the dry hardwood creates lots of dust.

After I blocked off the air injection system I was surprised to see that the air filter needed less cleaning, I had figured it would require more cleaning. It was only after I cut up a blackened stump with lots of charcoal that I realized what was happening. The charcoal dust was leaving a trail off the bar into the front of the front of the recoil housing.

The air injection system works well with chips, but with dust, the fines get sucked into the air box. It actually creates an extra load of fines into the air box.

cus_deluxe

terms of service violator

- Local time

- 9:01 PM

- User ID

- 393

- Joined

- Jan 3, 2016

- Messages

- 5,643

- Reaction score

- 27,011

- Location

- Michigan

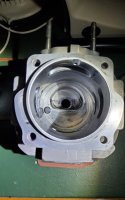

some weird lookin stuff goin on there. wonder what oil…

Ketchup

Epoxy member

- Local time

- 7:01 PM

- User ID

- 5594

- Joined

- Mar 12, 2018

- Messages

- 2,518

- Reaction score

- 8,474

- Location

- Colorado

- Local time

- 9:01 PM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,526

- Reaction score

- 150,441

- Location

- East Jordan, MI

RA is cleaner. My $ is on Klotz in one formulation or anotherLooks like Red Armor in the tank. The photo doesn’t show it very well, but one of the secondaries is slightly larger. No sign of backflow.

View attachment 372375

blacksmith

Pinnacle OPE Member

- Local time

- 9:01 PM

- User ID

- 4790

- Joined

- Dec 14, 2017

- Messages

- 756

- Reaction score

- 2,968

- Location

- central PA

- Local time

- 9:01 PM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,526

- Reaction score

- 150,441

- Location

- East Jordan, MI

Crazy symmetricalThis is my piston out of my 066 that I rebuilt. New tank from

@Glock37 and he powdered the cases.

I use aviation fuel with amsoil saber at around 32 : 1 mixture. I also mix sime marval mystery oil in with my straight gas before I put the 2 stroke mix in.

View attachment 373145

pbillyi69

Pinnacle OPE Member

- Local time

- 6:01 PM

- User ID

- 8788

- Joined

- Feb 21, 2019

- Messages

- 1,838

- Reaction score

- 4,946

- Location

- USA

i have a auestion about the wash patterns....in that last picture you can clearly see the swirling. are the clean spots where the mix is blowing around and the dark areas where the gases are at when the piston is at the top and explosion is happening?

Ketchup

Epoxy member

- Local time

- 7:01 PM

- User ID

- 5594

- Joined

- Mar 12, 2018

- Messages

- 2,518

- Reaction score

- 8,474

- Location

- Colorado

I would think that it’s more when the piston is near BDC. The swirls are from the edges of the upper port slowing down the charge…I think.i have a auestion about the wash patterns....in that last picture you can clearly see the swirling. are the clean spots where the mix is blowing around and the dark areas where the gases are at when the piston is at the top and explosion is happening?

Interesting how the squish band is clean all the way around on that one. @blacksmith, did you measure squish on that build?

blacksmith

Pinnacle OPE Member

- Local time

- 9:01 PM

- User ID

- 4790

- Joined

- Dec 14, 2017

- Messages

- 756

- Reaction score

- 2,968

- Location

- central PA

The only thing that I did was clean up the cylinder and open up the intake and exhaust. It does have a gasket on it. I did measure the squish. I can't say exactly what it was but I am thinking around .028" ?I would think that it’s more when the piston is near BDC. The swirls are from the edges of the upper port slowing down the charge…I think.

Interesting how the squish band is clean all the way around on that one. @blacksmith, did you measure squish on that build?

Dolkitafreak

Dolkita686

- Local time

- 9:01 PM

- User ID

- 7904

- Joined

- Nov 19, 2018

- Messages

- 540

- Reaction score

- 1,795

- Location

- Central Ohio

Redfin

Meh...

- Local time

- 9:01 PM

- User ID

- 159

- Joined

- Dec 24, 2015

- Messages

- 7,653

- Reaction score

- 40,039

- Location

- Central Pa

Still shows incoming charge squeezed out of squish band with the clean rim on chamber. That just interference fit? Any sealer?

Dolkitafreak

Dolkita686

- Local time

- 9:01 PM

- User ID

- 7904

- Joined

- Nov 19, 2018

- Messages

- 540

- Reaction score

- 1,795

- Location

- Central Ohio

Interference can crack cylinders if head is thin, I shoot for head .004” smaller than cylinder. They’ve been lapped together, and after lapping they do seal, but I add loctite 518 as insurance. Just lapped after good machine work passes p/v testing, any head saw gets tested…building a carb chasing an air leak makes you wanna pull your hair out, ask me how I know.Still shows incoming charge squeezed out of squish band with the clean rim on chamber. That just interference fit? Any sealer?

Similar threads

- Replies

- 24

- Views

- 3K