Maintenance Chief

Disrupting the peace with an old chainsaw

- Local time

- 8:32 AM

- User ID

- 11378

- Joined

- Jan 4, 2020

- Messages

- 4,215

- Reaction score

- 13,795

- Location

- South Carolina

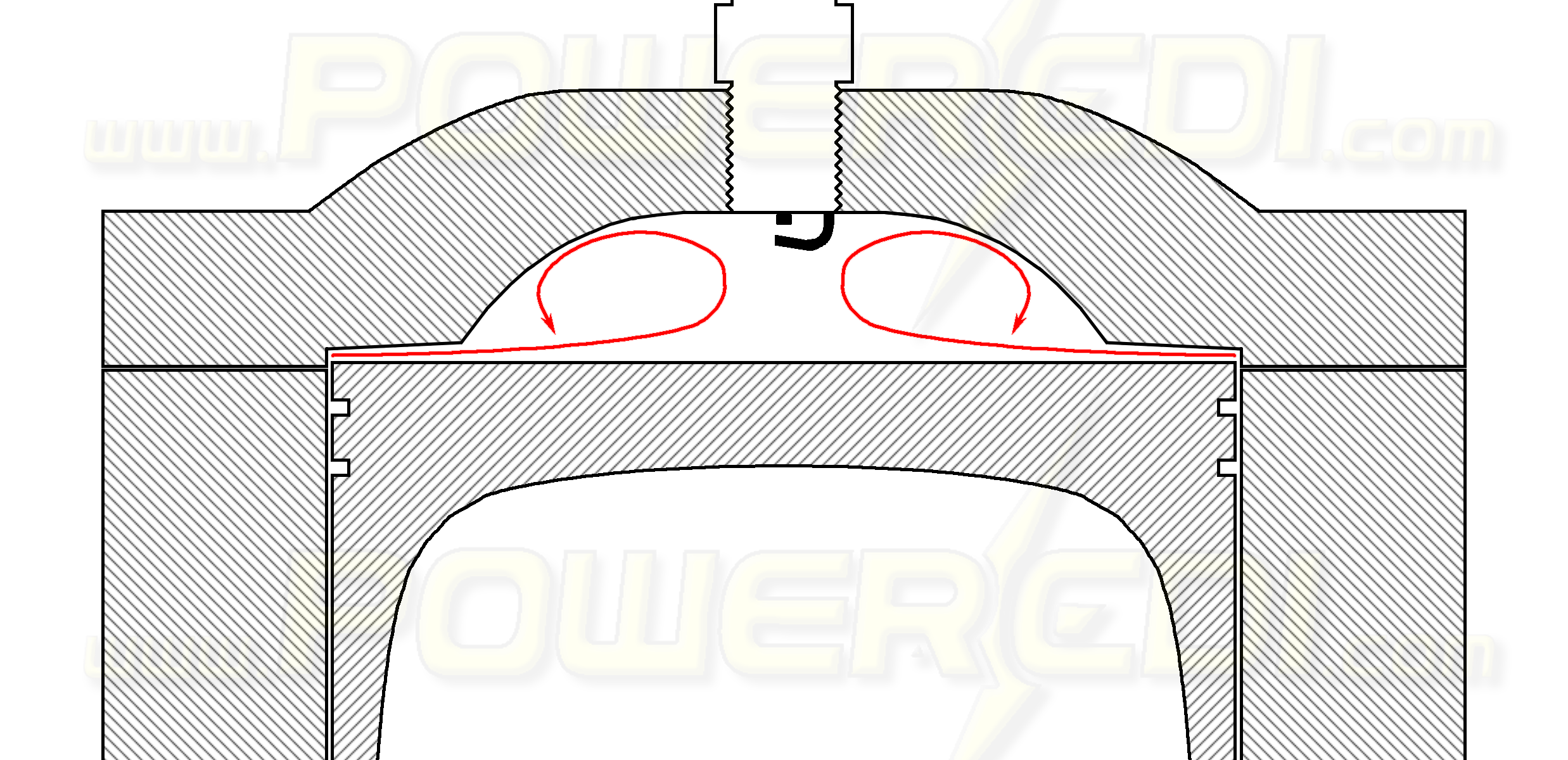

But, after a bump in compression alone, more fuel is needed. I’ve shaved cylinder heads and reduced head gasket thickness to increase compression. Every single time, I’ve needed to increase fuel flow.

While I agree that an increase in compression will increase the thermal efficiency of an engine, that’s not the only thing happening with the increase of compression. The motor also has a significant increase of intake vacuum, and correspondingly, an increase in fuel is needed

Part of the increase in compression is heat production, the molecules of air are more spread out in a hot environment, the need for more fuel is for expansion of the air molecules to join up with fuel. Extra fuel also cools the charge which also helps.

Just what I've read, but it is easier to see fuel condensing on a cold day .