You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oil questions...

- Thread starter SawAddictedFarmer

- Start date

pbillyi69

Pinnacle OPE Member

- Local time

- 10:46 PM

- User ID

- 8788

- Joined

- Feb 21, 2019

- Messages

- 1,843

- Reaction score

- 4,979

- Location

- USA

thats right. what i meant that it changes as it needs to so it stays running at max power without having to manually adjust a screwI believe its the opposite. Filter gets clogged, less air gets in. It leans the engine out to maintain rpm.

dangerousatom

Super OPE Member

- Local time

- 1:46 AM

- User ID

- 11828

- Joined

- Feb 25, 2020

- Messages

- 327

- Reaction score

- 922

- Location

- Quakertown, PA, United States

Air Temp and Altitude/Ambient air pressure and how smooth its running ( a knock sensor type detection ) is about all the new compy-controlled saws read. They control RPM with basically only those 3 things. That's why the don't run great at partial throttle.

From what I can tell the saws dont know what Octane your running or what mix ratio. I believe there is a "sweet spot" window that the programing is shooting for, thats why they are constantly adjusting while cutting or idling. With an EGT and O2 sensor you could squeeze more out, but that leads to a bigger control chip, more programing and the need for more sensors. Those additions on a small engine let alone a 2-stroke have way more failure potential and just issues in general. That along with a likely battery or winding like a heated saw has to run all the unneeded sensors.

IMO the new Auto-tuned/E-tronic saws are just a way to get big Gov/EPA to pat the company on the head and say good job we wont bother you for a could of years now. I dont even believe they are more efficient or cleaner in the long run of use. If they are less a saw in terms of power and reliability then your going to use more fuel to get the job done or buy more parts because of failure witch is basically fuel in one way or another.

-Getting the job done in the least time and fuel efficient way along with the use of the simplest, least "break down" equipment is always the most economical on all levels.

From what I can tell the saws dont know what Octane your running or what mix ratio. I believe there is a "sweet spot" window that the programing is shooting for, thats why they are constantly adjusting while cutting or idling. With an EGT and O2 sensor you could squeeze more out, but that leads to a bigger control chip, more programing and the need for more sensors. Those additions on a small engine let alone a 2-stroke have way more failure potential and just issues in general. That along with a likely battery or winding like a heated saw has to run all the unneeded sensors.

IMO the new Auto-tuned/E-tronic saws are just a way to get big Gov/EPA to pat the company on the head and say good job we wont bother you for a could of years now. I dont even believe they are more efficient or cleaner in the long run of use. If they are less a saw in terms of power and reliability then your going to use more fuel to get the job done or buy more parts because of failure witch is basically fuel in one way or another.

-Getting the job done in the least time and fuel efficient way along with the use of the simplest, least "break down" equipment is always the most economical on all levels.

Last edited:

- Local time

- 12:46 AM

- User ID

- 3210

- Joined

- May 17, 2017

- Messages

- 469

- Reaction score

- 1,533

- Location

- NE Wisconsin

Looking up the specifications of the referenced Dominator 2T oil, it‘s viscosity is listed in the US SAE 20 grade range so it should not be too thick.Not so simple. Thicker oil and lower temperatures and m tronic is kaput.

- Local time

- 1:46 AM

- User ID

- 325

- Joined

- Dec 30, 2015

- Messages

- 5,096

- Reaction score

- 25,384

- Location

- Centre County

Mtron is fine at 32:1. Don’t worry about oil ratios. The 50:1 BS came along with an EPA mandate for small engine emissions

bwalker

Pinnacle OPE Member

- Local time

- 1:46 AM

- User ID

- 523

- Joined

- Jan 12, 2016

- Messages

- 2,086

- Reaction score

- 4,844

- Location

- Montana

There is zero doubt they are cleaner and more efficient.Air Temp and Altitude/Ambient air pressure and how smooth its running ( a knock sensor type detection ) is about all the new compy-controlled saws read. They control RPM with basically only those 3 things. That's why the don't run great at partial throttle.

From what I can tell the saws dont know what Octane your running or what mix ratio. I believe there is a "sweet spot" window that the programing is shooting for, thats why they are constantly adjusting while cutting or idling. With an EGT and O2 sensor you could squeeze more out, but that leads to a bigger control chip, more programing and the need for more sensors. Those additions on a small engine let alone a 2-stroke have way more failure potential and just issues in general. That along with a likely battery or winding like a heated saw has to run all the unneeded sensors.

IMO the new Auto-tuned/E-tronic saws are just a way to get big Gov/EPA to pat the company on the head and say good job we wont bother you for a could of years now. I dont even believe they are more efficient or cleaner in the long run of use. If they are less a saw in terms of power and reliability then your going to use more fuel to get the job done or buy more parts because of failure witch is basically fuel in one way or another.

-Getting the job done in the least time and fuel efficient way along with the use of the simplest, least "break down" equipment is always the most economical on all levels.

- Local time

- 1:46 AM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,527

- Reaction score

- 150,451

- Location

- East Jordan, MI

SawAddictedFarmer

Pinnacle OPE Member

- Local time

- 12:46 AM

- User ID

- 34199

- Joined

- Sep 3, 2025

- Messages

- 719

- Reaction score

- 2,178

- Location

- Illinois

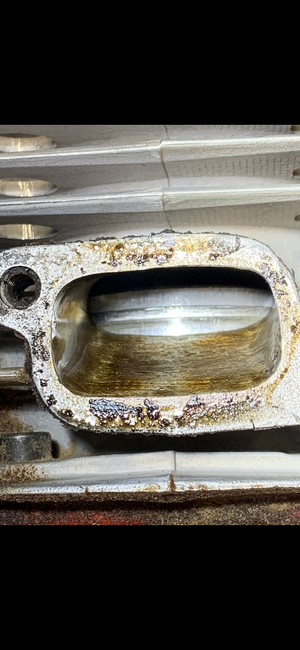

Sweet! That looks pretty good!I’ll share it again for the guys that haven’t seen it. This is dominator at 32:1 in my ported 2153 after about 25 gallons of fuel. It goes to every gtg with me and cuts maybe half of my firewood each year

Almost 0 carbon. No buildup anywhere

View attachment 471695View attachment 471696View attachment 471697

SawAddictedFarmer

Pinnacle OPE Member

- Local time

- 12:46 AM

- User ID

- 34199

- Joined

- Sep 3, 2025

- Messages

- 719

- Reaction score

- 2,178

- Location

- Illinois

I just wanted to be absolutely sure before running it in a really expensive saw!

You all are awesome!

You all are awesome!

- Local time

- 11:46 PM

- User ID

- 23623

- Joined

- May 30, 2022

- Messages

- 697

- Reaction score

- 2,122

- Location

- NW MT

did you make the switch to 32:1? I burned a gallon through my huskys at 32:1 and they did just fine, I'm going to be keeping it there from now on.I just wanted to be absolutely sure before running it in a really expensive saw!

You all are awesome!

SawAddictedFarmer

Pinnacle OPE Member

- Local time

- 12:46 AM

- User ID

- 34199

- Joined

- Sep 3, 2025

- Messages

- 719

- Reaction score

- 2,178

- Location

- Illinois

I haven't even had time to cut. We've been working on our biggest tractor that quit moving. Hopefully once it freezes and life slows down though. Any noticeable power difference?did you make the switch to 32:1? I burned a gallon through my huskys at 32:1 and they did just fine, I'm going to be keeping it there from now on.

- Local time

- 11:46 PM

- User ID

- 23623

- Joined

- May 30, 2022

- Messages

- 697

- Reaction score

- 2,122

- Location

- NW MT

cant say I noticed any power difference, plus I wasnt cutting very big trees.

- Local time

- 10:46 PM

- User ID

- 27954

- Joined

- Nov 24, 2023

- Messages

- 3,040

- Reaction score

- 9,856

- Location

- Northern Idaho, Ehh

How often do you have to clean your spark plugs (from normal use) or do they also stay just as clean?I’ll share it again for the guys that haven’t seen it. This is dominator at 32:1 in my ported 2153 after about 25 gallons of fuel. It goes to every gtg with me and cuts maybe half of my firewood each year

Almost 0 carbon. No buildup anywhere

tree monkey

Mastermind Approved!

- Local time

- 12:46 AM

- User ID

- 339

- Joined

- Dec 14, 2015

- Messages

- 4,948

- Reaction score

- 40,818

- Location

- wi

Woodtroll

Super OPE Member

- Local time

- 1:46 AM

- User ID

- 30208

- Joined

- Oct 7, 2024

- Messages

- 265

- Reaction score

- 902

- Location

- Mtns of SW VA

Maybe this guy knows what he's talking about; he keeps saying he's got 40 years of experience... But with his droning voice and hand-held camera shaking around I felt like I was on a deep-sea fishing boat in a storm with Eeyore. I could not finish watching.

- Local time

- 10:46 PM

- User ID

- 27954

- Joined

- Nov 24, 2023

- Messages

- 3,040

- Reaction score

- 9,856

- Location

- Northern Idaho, Ehh

Welcome to the forum. The use of mix oil at the manufacture's recommendation and everything in between is used by people here, there are lots of opinions and lots of people who have been running their numbers for years. From what I understand, the quality of oil is the biggest key. I switched from 50:1 to 40:1 as most of my saws I have are 1990's and earlier. Even the couple of newer ones I also run at 40:1.Why 32:1 and not the manufacturers recommendation of 50:1 ?

You can use the search function and find the many threads that discuss the different ratios and people's opinions about it.

Here is one thread:

The ignition of a car or a chainsaw is the same in that they bith have an advance curve. Wether it be mechanical(old cars) or electronic.I was taught that cars had mechanical accelerators in the ignition device, but in small devices this is not the case - the ignition is accelerated, which is why lower rotational speeds of these engines under load are unfavorable.

- Local time

- 1:46 AM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,527

- Reaction score

- 150,451

- Location

- East Jordan, MI

He definitely knows what he’s doing. He is tree monkey on here. Been porting saws for longer than anyone I knowMaybe this guy knows what he's talking about; he keeps saying he's got 40 years of experience... But with his droning voice and hand-held camera shaking around I felt like I was on a deep-sea fishing boat in a storm with Eeyore. I could not finish watching.

pbillyi69

Pinnacle OPE Member

- Local time

- 10:46 PM

- User ID

- 8788

- Joined

- Feb 21, 2019

- Messages

- 1,843

- Reaction score

- 4,979

- Location

- USA

if you read the paperwork that comes with most saws it says if using a different oil than they recomend to mix it at 32:1 because they cant verify that mixing other oils at 50:1 will be enough protection. 50:1 is for the epa mandates. 32:1 is just better.Why 32:1 and not the manufacturers recommendation of 50:1 ?

Similar threads

- Replies

- 92

- Views

- 6K