- Local time

- 2:59 PM

- User ID

- 26879

- Joined

- Jun 7, 2023

- Messages

- 1,757

- Reaction score

- 5,060

- Location

- Norcal

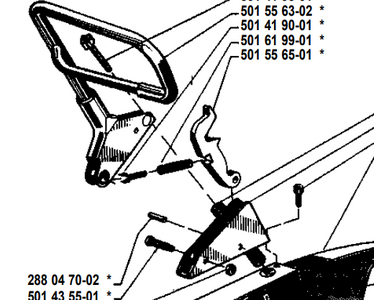

Transfers may be better where they're at after you raise exhaust to 104. Were mine, I'd run it that way before putting them back and see.No base gasket was:

106 ex

Transfers open 123

Intake 74

Thought to take 20/30 thou of both base and squish and finish exhaust at 104

Put transfers back to 17 BD

Widen intake a hair.

Good bad or ugly?

I'd most definitely advance timing with the base cut. Probably lower intake a couple degrees too.

Last edited: