el33t

Super OPE Member

- Local time

- 2:51 AM

- User ID

- 29908

- Joined

- Aug 28, 2024

- Messages

- 277

- Reaction score

- 690

- Location

- Poland

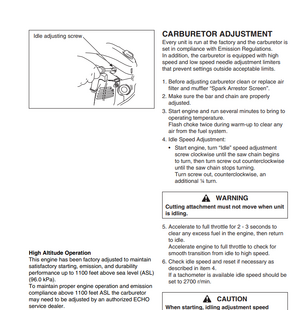

Matter of fact, I encountered this very problem on my new to me MS-194C yesterday. It would die out after a long cut. I richened the low side a wee bit and reset the idle speed screw according to factory instructions: turn it in until the chain turns, turn back out until chain stops, turn back out one full turn. It now returns to idle just fine, although it sounds fast to my ears. Stihl doesn't publish a spec for what the final idle speed should be on this saw, as long as it runs well I'm going to leave it as is. I suspect it may be able to idle down more as it breaks in, I honestly believe this saw still had dealership fuel in the tank when I bought it.

Officially, the idle speed for MS 194 is 3000 rpm.

I think it is unlikely that enriching the idle mixture with the L screw helps in such cases. The mixture for low revs is adjusted in such a way as to achieve satisfactory acceleration, i.e. on the rich side of “optimum” (when the idle speed reaches its maximum). It is much more likely for carburetors with an independent idle system that after closing the throttle, the mixture will be too rich, causing the speed to drop below the speed at which the engine will stall.

If you enrich the mixture with the L screw, the engine speed drops instead of increasing. Assuming, of course, that the factory settings are reasonably correct (on the rich side of the "optimum").

When the idle mixture is leaner than recommended by the manufacturer, the engine speed does not drop as quickly and a situation can occur where in the case of chainsaws, after closing the throttle, the speed is still higher than the clutch engagement speed for a moment.

In summary, in such cases, when the chainsaw is in working order, it is sufficient to increase the idle speed in accordance with the instructions by using the idle speed screw, finding the speed at which the clutch engages, and then reducing the speed by one turn of the screw in the case of the MS 194 (this varies for different models). The procedure for adjusting the idle speed is included in the manuals of most chainsaws, as problems with this are common. See, for example, this recent thread:

According to standards, for safety reasons, the clutch engagement speed should be at least 25% higher than the idle speed. So if you set the idle speed to 3000 rpm, the clutch should engage at 3750 rpm at the earliest.