- Local time

- 11:33 AM

- User ID

- 4

- Joined

- Dec 3, 2015

- Messages

- 52,954

- Reaction score

- 352,753

- Location

- Banner Springs Tennessee

I appreciate that too.Understood. I only pointed it out to save the op some frustration.

I appreciate that too.Understood. I only pointed it out to save the op some frustration.

I thought about that after I got it all reassembled, will do before I get it back in the machine!Trim the limiter tabs off the carb screws while they are right out in the wide open.

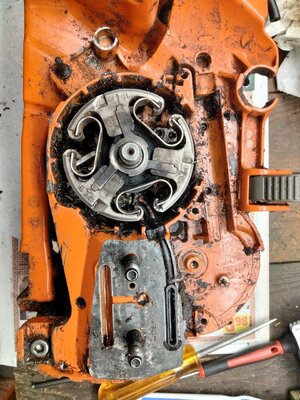

I’ll say one thing, 576’s are silky smoothClutch cover and associated parts are cleaned, needle bearing will be greased before re-installation.

View attachment 404236

Looking at the rim sprocket, what is a good way to tell if it is ready to be replaced when looking at it? I know Stihl recommends changing them every two chains, but what is your practice?

View attachment 404237

Next up is the chain brake assembly....dirty image first:

View attachment 404238

Parts after cleaning. Will have to wait until I clean the main body to put them all back in.

View attachment 404240

That one will run awhile longer.Looking at the rim sprocket, what is a good way to tell if it is ready to be replaced when looking at it? I know Stihl recommends changing them every two chains, but what is your practice?

Thanks, I have not run a saw long enough to have to change one out yet, but have seen a few come in the shop that were obviously ready for a change, especially those that converted from a one piece rim to a two-to-three piece rim...That one will run awhile longer.

I appreciate the reference photos. Unfortunately I do not have access to a mill, I will have to look for another way, maybe with an angle grinder or something. That does give me a better idea what I need! I am definitely going to get the clutch off before this all goes back together, just getting off all the crap on the outside, so there is less chance of it getting around the crank. The last 372 I worked on had issues with the crank going around, come to find out when someone else took off the cylinder, they knocked some junk in there and apparently there was a 1/2" long piece of metal that got in there and prevented the cylinder from going around. I flushed it a couple of times with mix fuel and it finally washed out and the crank could spin freely.Pics for reference. If you have access to a mill this will be easy. I made mine with a death wheel in a 4” grinder iirc… It’s been awhile. Or buy one but what’s the fun in that?

I made my clutch removal socket with a 4.5" grinder/cut off wheel.

I jamb a wooden dowel, plastic handle,rope,rag, or whatever into the crankcase to hold the crankshaft while removing the clutch. A scrench through the wrist pin resting on some blocks works to.

I've taken a big adjustable wrench and closed the jaws in the clutch and turned it off with another adjustable wrench too.

I might have to try the adjustable wrench trick...but in the end I might be best off buying the actual tool...depends on how badly I scrape up my knuckles in the process...lol.I made one myself as well, but the clutch was so tight I couldn't get it to work.

Ended up losing patience and hitting it with a punch and a hammer. Damaged more than I should have.

Then I ordered the official clutch tool and it really works the best for me.