farminkarman

I like the red & black ones

- Local time

- 10:02 AM

- User ID

- 13535

- Joined

- Aug 17, 2020

- Messages

- 5,025

- Reaction score

- 29,026

- Location

- Neenah Wisconsin

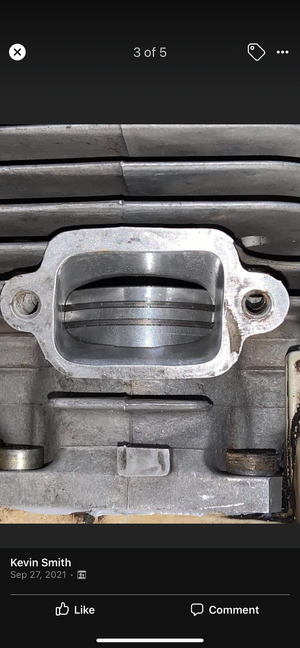

I was very impressed with the quality of the Duke's Reserve cylinder. I cut 0.040" from the band which got the exhaust to 99, the intake landed at 84, and I raised the transfers to 120. Once I got the saw tuned right it was a beast with a long bar. The intake duration was a bit long for a racier build, but seemed to work very well for what I built it for.

Edit: I forgot to mention that the upper transfers on the Duke's jug blow harder back toward the intake than a FT cylinder, which I think is a plus for a long bar saw.