Doing a bit of reserch..

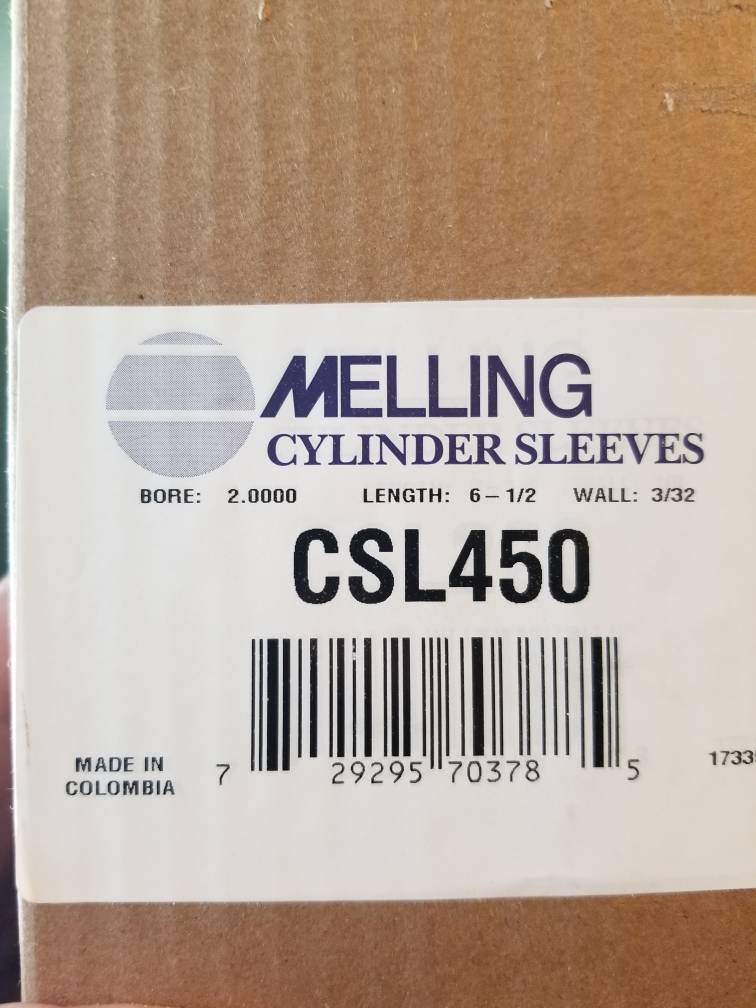

Melling offers some sleeves in .0625" wall for some applications. Feel that is a good number to shoot for.

I'm going to make a torque plate fixture. So the jug can be torqued down like it was in the case, Then bored.

With the squish cutting/rod set up I feel it puts extra pressure on the walls especially during an over bore.

Just a thick plate, inside of a thick walled tube that the jug bolts in with the 4 base bolts. Feel that will give a more accurate bore. And allow honing on the lathe

Sent from my SM-G950U using Tapatalk

Melling offers some sleeves in .0625" wall for some applications. Feel that is a good number to shoot for.

I'm going to make a torque plate fixture. So the jug can be torqued down like it was in the case, Then bored.

With the squish cutting/rod set up I feel it puts extra pressure on the walls especially during an over bore.

Just a thick plate, inside of a thick walled tube that the jug bolts in with the 4 base bolts. Feel that will give a more accurate bore. And allow honing on the lathe

Sent from my SM-G950U using Tapatalk