"perfect" and/in this head is an oxymoron

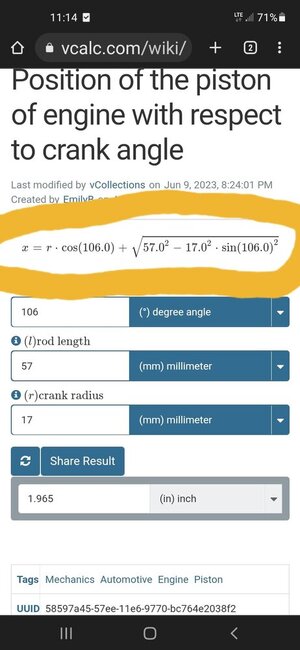

I guess my aim is to be accurate. Being that I'm so green to all of this, I may be picking less than perfect goals. I've no idea what I'm chasing... But I suppose if my theory is to keep the uppers as tight as possible, and land the exh where I want it, I have less material to remove to raise the uppers to achieve a recommendation for blowdown. Thereby, in my theoretical world, I have less to remove from lowers (if any, as with perhaps a dual port jug) to have a gradient, smooth path from a slightly larger area, to a smaller area to facilitate velocity at the uppers. As far as intake goes, I like the idea of less is more, at least to start. I've learned from you guys the value of maintaining case compression, and vacuum, in many cases. I've a feeling my dislexia has me working backwards from how most of you fellers do. I work the band up, in my math, after determining the base. So for my methodology, the band is a symptom of landing timing. But I digress, I think my math is fugged up on this one.