Today was a good freaking day!

On the road at 6:30 am. Picked up my buddy Will at 6:45 and we headed south.

Arrived at 8:40 am. Got unloaded and got to work.

Hit the bolts on the monster winch access cover with some 50/50. They came off with ease. Immediately inside was where the two cables entered the winch housing, one for brake, one for engage/disengage. Will managed to free up the brake lever with some 50/50 and elbow grease. We couldn't get the engage/disengage cable to free up, so we cut the cable at the winch with a death wheel and unthreaded the stub from the actuating lever inside the winch. Once that was done, we freed up the lever with equal applications of 50/50, brute force, and curse words. Once we had the engine turning over later in the day, we figured out which position was neutral and left it there so the winch wouldn't spin when the engine was turning over.

View attachment 402330

We worked on the clutch brake next. Yes, the clutch brake; it has a wet clutch (submerged in oil) and there's a brake shoe that rides on the clutch to keep the clutch from turning when the clutch is disengaged. The clutch brake is actuated by the main clutch lever moving all the way forward. Checked the oil level in the clutch and it was good; oil was clean, too. Anyway, we figured out that the clutch brake was not actuating as it should have been when I tried to start the tractor last time, but I managed to get it in place to where it would actuate if the brake itself wasn't junk...more on this later.

View attachment 402331

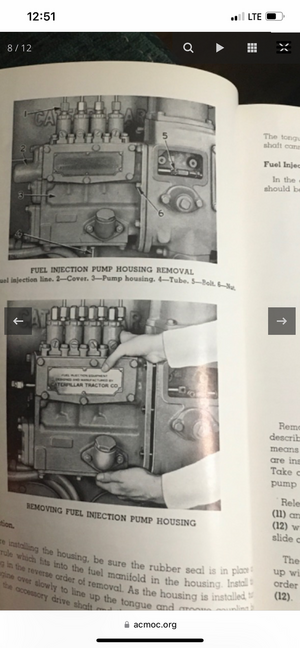

Next we worked on the fuel system. I removed the cover to the rack and hosed everything down with 50/50. Then, with Will watching the rack, I spun the tractor over using the HF 24v jump pack. Will reported that all the spring loaded plungers were moving up and down except for one, which was stuck in the up position. So I managed to gently persuade it to move back down to where it was in contact with the cam...and then spun the engine over again...and it stuck up again... We went back and forth for about 10 iterations of application of 50/50 and gentle persuasion and finally the plunger moved up and down its own.

View attachment 402332

At that point, we weren't trying to start the engine, and we weren't building oil pressure, but I did see a slight puff of smoke from the exhaust, so then I cracked open the fuel lines at the injectors about 1/2 turn. Spun it over some more and got a fair amount of fuel flowing from each fuel line, so I snugged them down and decided to see if she would crank.

Now that it had been spinning over for a while, the jump pack was getting a bit tired, so we went up to the owner's house and picked up the pair of 8D batteries. Wired them up for 24V and gave her the beans. I didn't get much of anything with the decompression lever in the START position, but when I switched it to the RUN position, I started getting some smoke out the exhaust, so I gave her a little whiff of ether. Engine picked up and started to catch like it was going to start. This happened a few times and then she lit for good! It was running fairly rough at first, but that's because I didn't have the decompression lever all the way shut. Once I shut it, she cleaned up and idled nicely! Great oil pressure, too!

From there, I tried to get her to move by putting the forward/reverse lever in either forward or reverse, but no such luck; all it would do is grind and I wasn't about to force it. Even with the clutch lever in the disengage position and the clutch brake on, the clutch still seemed to be dragging. I could see the driveshaft spinning, too, so I suspect the clutch brake is smoked.

At that point, we were out of time and had to head north back to San Antonio.

On the way back I spoke with a guy who owns a D7 of similar vintage (D7E) and he said he has had a similar clutch brake problem with his, and he will just crank the engine over with the tractor in forward and low gear. That will either actually start the dozer in gear or it will break the clutch free so it's no longer dragging.

On the way home I also spoke with the D7D owner (he's out of town for work) and he's tickled pink that the old girl is running again.

Plan is to head back out there again in the next week or so to drain the water out of the transmission (we didn't have the correct tool to remove the drain plug) and see if we can actually get it to move.

FYI - I love to complain about south Texas summers, but days like today do NOT suck - sunny and highs in the low 70's. I was in short sleeves at the end of the day.

I'll work on editing the video over the next few days and will post to my YT channel.