- Local time

- 12:59 PM

- User ID

- 26310

- Joined

- Mar 13, 2023

- Messages

- 1,033

- Reaction score

- 2,910

- Location

- Maryland, USA

You've helped me see about case volume. That's what inspired me to keep the uppers tight and limit the shaping of the lowers on this saw. The side feed saws, well, I'm afraid to do anything but FILL the lowers to RAISE case compression.

I had a few base plates with multiple sets of holes and then one day said “Yeah fugg that”.I've got one for you fellas. Elementary I'm sure, but something I'm challenged by regardless. When I'm making baseplates (lathe fixture plates) on these saws with asymmetrical bolt patters, I try and be accurate with my layout. My datum is always center of bore. I always drill a small hole here, and bring in the tailstock to press it against the 4 jaw chuck head nearly dead nut to center. However, I'm struggling with a good way to place the bolt holes perfectly in relationship said center of bore. I measure the distance between holes on exh side, add bolt hole bore diameter, divide by 2. Repeat between intake side. Then I get a diagonal measurement same way for reference. My challenge (use 361 as example), is placing the bolt pattern off center between intake and exh. I don't have pin gauges yet. My thought would be to place them in the bolt holes, then put a parallel across them, then measure from bore edge to parallel, subtract thickness of parallel, then subtract half of bolt hole diameter, then add half of cyl bore diameter. After all that, I'd be at the mercy of bolt hole tolerance which I'm measuring to be pretty loose. Anyway, I'm sure someone will tell me to quit wasting my time, Chuck it up, and dial it in with the 4 jaw.. But I'm really aiming to streamline setup time and accuracy at the lathe. Appreciate the input in advance!

Wow! That's getting your money's worthI had a few base plates with multiple sets of holes and then one day said “Yeah fugg that”.

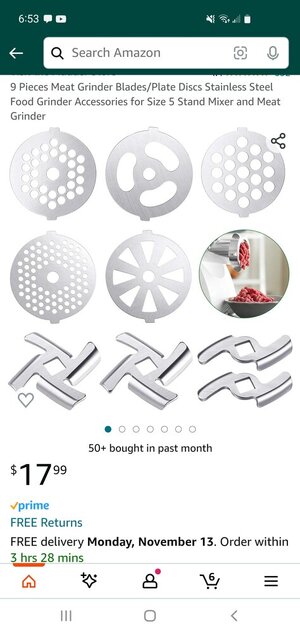

View attachment 396308

What's your method now? 3 saws per plate? Do you worry about centering?I had a few base plates with multiple sets of holes and then one day said “Yeah fugg that”.

View attachment 396308

I had a few base plates with multiple sets of holes and then one day said “Yeah fugg that”.

View attachment 396308

All saws per plate. I did that 5-6 years ago and it’s the only one I’ve used since.What's your method now? 3 saws per plate? Do you worry about centering?

Earlier this year I ported a 362 that wouldn't behave after the port job. The saw was consistently going lean, and the owner sent it back to me. After running some test cuts, I quickly concluded the carb was starving for fuel under load. I pulled the m-tronic solenoid as you did, and I found the orifices to be around 0.045". The needle seat was only 0.023". I made the decision to drill out the needle seat to 0.033" and polished it. I put the saw back together and life was good. The saw actually was a touch fat on top until the m-tronic dialed in the tune....it also picked up a good amount of mid-range power after the carb mod. IIRC, I took 0.045" from the band, advanced the timing ~8 degrees, and had 106, 124-127, 78. It was easily the strongest 60cc I have built so far.View attachment 395864

This is the solenoid bore. I already went up a size on the seat. The hole on the left leads to the nozzle. Brass one on right leads to idle and transition? I drilled that up from 0.35mm, to 0.4mm. Probably a mistake. Looks as though the main comes hogged already. I drifted the nozzle out, and the hole in the side of that matched the (likely over 1mm) hole in the chamber. Take me to class fellas. Anyt threads on here you recommend, etc. I'm all ears! As always, thanks in advance for your hard earned expertise!

I'll be going I back into this 362 and porting it like I have a pair. I did a sissy port because I was skeered. And it's marginally better than stock. I simply didn't take enough. And all my worrying about it being lean and claiming it screams... Well, it's mtronic so the first is paranoia and the second is the mtronic just being badass.Earlier this year I ported a 362 that wouldn't behave after the port job. The saw was consistently going lean, and the owner sent it back to me. After running some test cuts, I quickly concluded the carb was starving for fuel under load. I pulled the m-tronic solenoid as you did, and I found the orifices to be around 0.045". The needle seat was only 0.023". I made the decision to drill out the needle seat to 0.033" and polished it. I put the saw back together and life was good. The saw actually was a touch fat on top until the m-tronic dialed in the tune....it also picked up a good amount of mid-range power after the carb mod. IIRC, I took 0.045" from the band, advanced the timing ~8 degrees, and had 106, 124-127, 78. It was easily the strongest 60cc I have built so far.

I don’t use the tailstock or a mandrel to center or dial in the jug in the 4 jaw so not certain. I use a long reach dial indicator on the x and y axis inside the jugSeems I'm wasting expensive aluminum plate. And time for that matter. I've been hyper analyzing this with each plate. Making the plate has been my speed bump. I will say, the ones I've done so far, using the tailstock to center, I'm only off like 10 to 15 though before dialing in. Saves some time chasing Jaws. However, I also spend alot of time trying to get the jug to stay still in the fixture when it isn't flat on top. 361,362,have a milled spot on top center. I support the jug on a socket that measures parallel end to end. That keeps it pretty flat. Then, I can mostly focus on making it concentric. The 026,038 were a pita, as I hadn't figure a good way to mill a portion of the top parallel with the base.

Same here with the indicator. I recently procured a nice used Browne and Sharpe.I don’t use the tailstock or a mandrel to center or dial in the jug in the 4 jaw so not certain. I use a long reach dial indicator on the x and y axis inside the jug

Idk. Used to take me 45 minutes, now takes me 10-15. Loosen one, tighten the other. Over and overWhat I like about centering with the tail stock, is less jaw walking. I'm sure I'm doing something wrong to cause this, but it seems the longer the adjustment I need to make, the more possible it is to "loose my grip", and if I'm not careful, create space between the plate and chuck face. This then requires more massaging. Minus happy ending.

OK OK. I'll be patient.Idk. Used to take me 45 minutes, now takes me 10-15. Loosen one, tighten the other. Over and over

I find center of the plate and then use a base gasket to set the holes. After making a bunch of plates, you’ll find that most saws will fit what you have made with a few exceptions. Then I just stamp and “E” and the model on the exhaust side of the plate.I've got one for you fellas. Elementary I'm sure, but something I'm challenged by regardless. When I'm making baseplates (lathe fixture plates) on these saws with asymmetrical bolt patters, I try and be accurate with my layout. My datum is always center of bore. I always drill a small hole here, and bring in the tailstock to press it against the 4 jaw chuck head nearly dead nut to center. However, I'm struggling with a good way to place the bolt holes perfectly in relationship said center of bore. I measure the distance between holes on exh side, add bolt hole bore diameter, divide by 2. Repeat between intake side. Then I get a diagonal measurement same way for reference. My challenge (use 361 as example), is placing the bolt pattern off center between intake and exh. I don't have pin gauges yet. My thought would be to place them in the bolt holes, then put a parallel across them, then measure from bore edge to parallel, subtract thickness of parallel, then subtract half of bolt hole diameter, then add half of cyl bore diameter. After all that, I'd be at the mercy of bolt hole tolerance which I'm measuring to be pretty loose. Anyway, I'm sure someone will tell me to quit wasting my time, Chuck it up, and dial it in with the 4 jaw.. But I'm really aiming to streamline setup time and accuracy at the lathe. Appreciate the input in advance!