- Local time

- 10:54 PM

- User ID

- 309

- Joined

- Dec 29, 2015

- Messages

- 7,958

- Reaction score

- 50,488

- Location

- Ontario, Canada

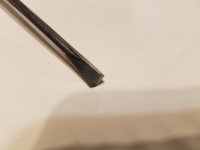

I'd be looking for something about .012" thick. Maybe check how thick a greeting card or a cereal box is.Now what do I do for a gasket?

@paragonbuilder how thick was the roof flashing you used?