You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

STIHL The Official Stihl Chainsaws Thread

- Thread starter Greenthorn

- Start date

- Local time

- 1:52 AM

- User ID

- 2523

- Joined

- Jan 24, 2017

- Messages

- 4,943

- Reaction score

- 22,891

- Location

- Berkshire County, Massachusetts

Me too buddy, me too.I hope all turns out well for you Nick!

lehman live edge slab

Live Action

- Local time

- 12:52 AM

- User ID

- 3953

- Joined

- Sep 2, 2017

- Messages

- 3,399

- Reaction score

- 11,836

- Location

- Mn

Anyone use the nova chip on a stihl 031? I used one on a 032 worked great but now I put one on a points style 031 and it runs well but seems down on power. Acceleration is kinda lazy also, saw has 150 psi and I’m wondering if the module retarded the ignition some causing the lower power. I’m thinking of trimming key some and give a little advance to see if it helps. I’ve also read some people were using electronic flywheels but was also told to use only the points style. Not a large fan of the nova chips seem to be pretty high failure rate but it’s the main option at the moment. I think the now unavailable atom chips were more specific to use and better. Friend of mine that’s an electrical engineer is making some atom style chips for me. Few slightly different versions to find the best one for different saw applications. After

It’s all sorted out and we know they’re reliable I’m sure we will have some to sell so people can keep the old saws going.

It’s all sorted out and we know they’re reliable I’m sure we will have some to sell so people can keep the old saws going.

lehman live edge slab

Live Action

- Local time

- 12:52 AM

- User ID

- 3953

- Joined

- Sep 2, 2017

- Messages

- 3,399

- Reaction score

- 11,836

- Location

- Mn

Sorry the more I look this has been brought up before and I need to advance the ignition the way it sounds. So I’m wondering if I should try the electronic flywheel and see or if it will be too much advance. I’ll look at them both when I get home, and after it’s all sorted out maybe my friend can alter the timing in the electronic chip he’s making. Taylor one to the 031 points and one to the 031 electronic so it will be a simple hookup and mount it deal.

lehman live edge slab

Live Action

- Local time

- 12:52 AM

- User ID

- 3953

- Joined

- Sep 2, 2017

- Messages

- 3,399

- Reaction score

- 11,836

- Location

- Mn

Well looked at both flywheels and if they are indexed using the keyway the electronic one’s magnets are exactly one cooling fin off to the advanced side. So while not the most scientific way to determine it being the flywheel has 24 fins and if you divide 360 by 24 each fin represents 15 degrees. So since the electronic flywheels magnets are one fin off it should fire 15 degrees earlier than the points flywheel. I tried the electronic flywheel on saw and it runs like a champ. Now the saw has the electronic flywheel, points coil and a nova 2 chip. Runs perfect and has the power and acceleration it should.

Homemade

Pinnacle OPE Member

- Local time

- 1:52 AM

- User ID

- 2986

- Joined

- Apr 8, 2017

- Messages

- 1,106

- Reaction score

- 2,699

- Location

- Wisconsin

Any ideas on removing the flywheel on an 090G without using the Stihl flywheel removal tool? I managed to get a 3jaw puller on it and gave her a few whacks with a hammer to no avail. It is soaking in penetrating oil. I don’t want to use heat cause of the ignition component behind it.

Any suggestions

Any suggestions

lehman live edge slab

Live Action

- Local time

- 12:52 AM

- User ID

- 3953

- Joined

- Sep 2, 2017

- Messages

- 3,399

- Reaction score

- 11,836

- Location

- Mn

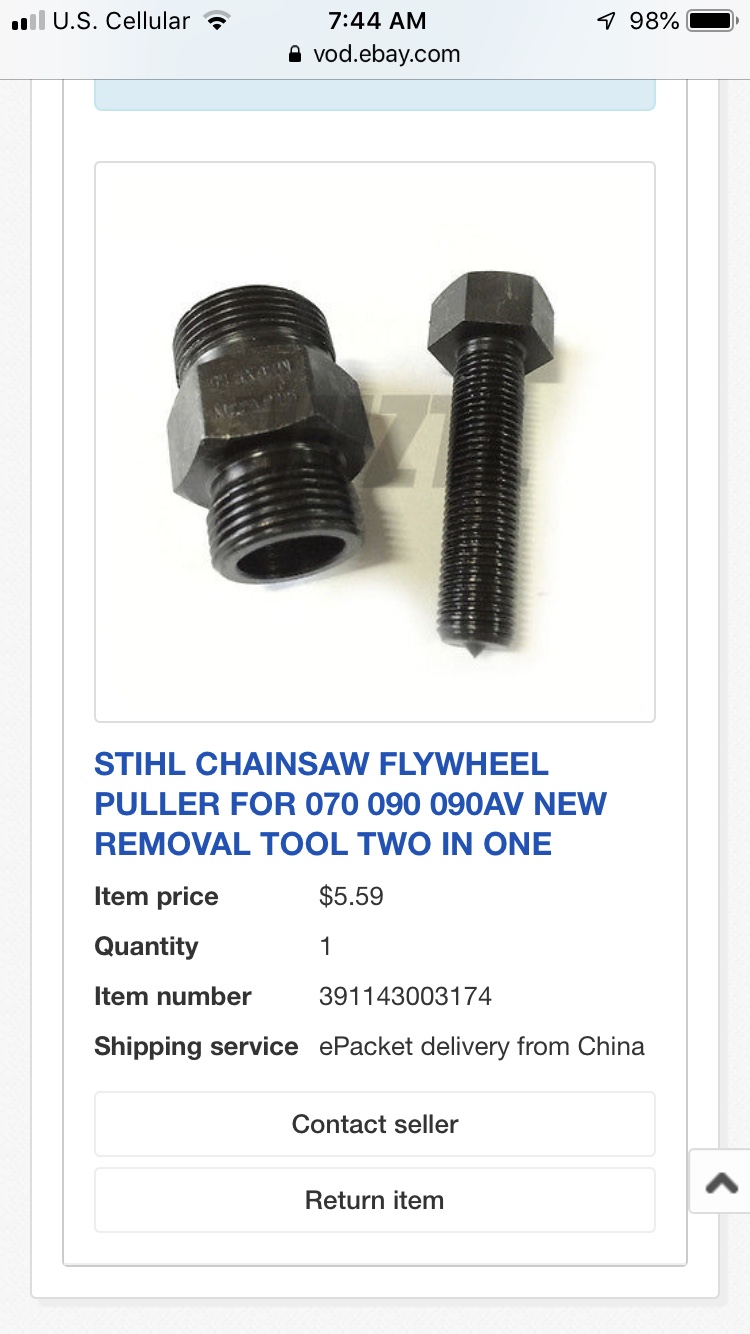

I wouldn’t use a three jaw puller you can wreck the flywheel. Need to pull it from the center I bought the double sided aftermarket puller to remove them off eBay for like 15$. To me it isn’t worth wrecking stuff without it

mdavlee

Hillbilly grinder

- Local time

- 1:52 AM

- User ID

- 279

- Joined

- Dec 28, 2015

- Messages

- 14,194

- Reaction score

- 64,603

- Location

- TN

Any ideas on removing the flywheel on an 090G without using the Stihl flywheel removal tool? I managed to get a 3jaw puller on it and gave her a few whacks with a hammer to no avail. It is soaking in penetrating oil. I don’t want to use heat cause of the ignition component behind it.

Any suggestions

Little heat from a heat gun or hair dryer and penetrating oil should do it. Don’t use a propane torch on it.

lehman live edge slab

Live Action

- Local time

- 12:52 AM

- User ID

- 3953

- Joined

- Sep 2, 2017

- Messages

- 3,399

- Reaction score

- 11,836

- Location

- Mn

lehman live edge slab

Live Action

- Local time

- 12:52 AM

- User ID

- 3953

- Joined

- Sep 2, 2017

- Messages

- 3,399

- Reaction score

- 11,836

- Location

- Mn

I was going to make one myself with a lathe but wasn’t even worth my time for 10-15$

Homemade

Pinnacle OPE Member

- Local time

- 1:52 AM

- User ID

- 2986

- Joined

- Apr 8, 2017

- Messages

- 1,106

- Reaction score

- 2,699

- Location

- Wisconsin

I was going to make one myself with a lathe but wasn’t even worth my time for 10-15$

That’s what I thought too. Or borrow one from someone on here and pay shipping both ways for rental fee.

PogoInTheWoods

Pinnacle OPE Member

- Local time

- 1:52 AM

- User ID

- 1190

- Joined

- Apr 23, 2016

- Messages

- 1,943

- Reaction score

- 3,850

- Location

- Ohio

I'd go with the Bosch/Puch flywheel puller version from Treatland.

https://www.treatland.tv/puch-bosch-flywheel-puller-p/puch-bosch-flywheel-puller.htm

Had mine for years and pulled dozens of flywheels with it. Very high quality and fast shipping. Wouldn't trust a 5 buck cheapie puller as far as I could throw it.

As for other handy specialty tools, the Husky case splitter comes to mind. Hafta pry the forks apart to straddle larger Stihl cranks, but it works great all the way around for most saws.

https://www.ebay.com/p/Chainsaw-Case-Crankcase-Splitter-Tool-for-STIHL-Husqvarna-Others/1268638138

There's even a guy in Indiana making these available as kits for $35 if you can weld.

https://www.treatland.tv/puch-bosch-flywheel-puller-p/puch-bosch-flywheel-puller.htm

Had mine for years and pulled dozens of flywheels with it. Very high quality and fast shipping. Wouldn't trust a 5 buck cheapie puller as far as I could throw it.

As for other handy specialty tools, the Husky case splitter comes to mind. Hafta pry the forks apart to straddle larger Stihl cranks, but it works great all the way around for most saws.

https://www.ebay.com/p/Chainsaw-Case-Crankcase-Splitter-Tool-for-STIHL-Husqvarna-Others/1268638138

There's even a guy in Indiana making these available as kits for $35 if you can weld.

- Local time

- 10:52 PM

- User ID

- 193

- Joined

- Dec 24, 2015

- Messages

- 4,534

- Reaction score

- 17,430

- Location

- Oregon

Be careful with the aftermarket ones on the 090’s.....not a whole lot of threads to engage. I had mine strip out on the 090. Still works perfectly on everything else though.

Al Smith

Here For The Long Haul!

- Local time

- 1:52 AM

- User ID

- 537

- Joined

- Jan 14, 2016

- Messages

- 6,125

- Reaction score

- 13,527

- Location

- North western Ohio

Before they were so cheap I used metric hydraulic tube banjo fittings which I think were 22 MM for smaller Stihl saws .I think I used 12 MM bolts or 1/2" fine thread which were a perfect fit for the ID of the fitting to make the pullers which worked well .Keep in mind I retired from an automotive engine plant and had access to tons of goodies I could adapt limited only to the imagination .

Homemade

Pinnacle OPE Member

- Local time

- 1:52 AM

- User ID

- 2986

- Joined

- Apr 8, 2017

- Messages

- 1,106

- Reaction score

- 2,699

- Location

- Wisconsin

Be careful with the aftermarket ones on the 090’s.....not a whole lot of threads to engage. I had mine strip out on the 090. Still works perfectly on everything else though.

The flywheel or the tool striped out? I’ll be careful and not use the impact. I can be patient. Might even try the heat gun.

Similar threads

- Replies

- 2

- Views

- 195

- Replies

- 11

- Views

- 328