Adamski

Plebus Splederns

- Local time

- 1:33 PM

- User ID

- 3128

- Joined

- May 3, 2017

- Messages

- 1,120

- Reaction score

- 2,684

- Location

- Essex, UK

So here it is, hopefully a thread with pictures. I have rebuilt from scratch a few saws and each time I miserably forget to take and add pictures of the build. This time I have made an attempt.

This is the saw I have been hunting for for a long time, A non starting 262xp with a clean OEM piston and original kolbenschmidt non decomp cylinder and silky smooth bearings. It will fire on choke and either rev up or die, think a full rebuild is needed.

All things after stripping the saw seem to be original or OEM, so this is promising.

Firstly a quick wash and degrease to save me the hassle of dirt everywhere... and this is what I ended up with, not too shabby for a 17-18 year old saw..

Then a full strip down of the saw, popped the seal cover of the flywheel side and the seal had gone brittle and perished, forgot to take a picture of the seal but here is one after I had pressed a new one in to the cover plate ready to re fit the screws with thread lock..

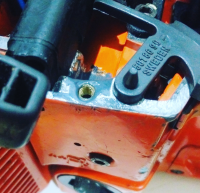

Next item, tackle the clutch side. Once again forgot to take picc's but this is better than my usual efforts. Took ages to prise the cover washer off the crank so that the oiler could be removed. Next had a mission to get the brass worm gear off the crank to access the seal. Here is another picture part way through reassembly, ready for the 3 allen screws and some more thread lock. All in all this saw is pretty clean I think.

Reassembly of the flywheel and coil, advanced the timing all of 1 degree to compensate for my hopeful gasket delete or squish of around .20" .... if it doesn't suit the saw I will set the timing back to stock. Coil gap set to factory. New flywheel nut added as previous owner had stripped the threads (crank threads A.O.K still)

Next up had to heat shrink the kill switch ground to the spark plug lead as the clips on the flywheel cover are snapped amd the wire drops down from the channel. Once again no image, I will get one soon (and the kill switch wire is not in situ in the pic)...

This is the saw I have been hunting for for a long time, A non starting 262xp with a clean OEM piston and original kolbenschmidt non decomp cylinder and silky smooth bearings. It will fire on choke and either rev up or die, think a full rebuild is needed.

All things after stripping the saw seem to be original or OEM, so this is promising.

Firstly a quick wash and degrease to save me the hassle of dirt everywhere... and this is what I ended up with, not too shabby for a 17-18 year old saw..

Then a full strip down of the saw, popped the seal cover of the flywheel side and the seal had gone brittle and perished, forgot to take a picture of the seal but here is one after I had pressed a new one in to the cover plate ready to re fit the screws with thread lock..

Next item, tackle the clutch side. Once again forgot to take picc's but this is better than my usual efforts. Took ages to prise the cover washer off the crank so that the oiler could be removed. Next had a mission to get the brass worm gear off the crank to access the seal. Here is another picture part way through reassembly, ready for the 3 allen screws and some more thread lock. All in all this saw is pretty clean I think.

Reassembly of the flywheel and coil, advanced the timing all of 1 degree to compensate for my hopeful gasket delete or squish of around .20" .... if it doesn't suit the saw I will set the timing back to stock. Coil gap set to factory. New flywheel nut added as previous owner had stripped the threads (crank threads A.O.K still)

Next up had to heat shrink the kill switch ground to the spark plug lead as the clips on the flywheel cover are snapped amd the wire drops down from the channel. Once again no image, I will get one soon (and the kill switch wire is not in situ in the pic)...

Last edited:

![IMAG1625[1].jpg IMAG1625[1].jpg](https://opeforum.com/data/attachments/77/77296-785cdb5d31ee807142514e355a32e61e.jpg)