- Local time

- 3:32 AM

- User ID

- 9318

- Joined

- Apr 24, 2019

- Messages

- 1,820

- Reaction score

- 7,594

- Location

- Waleska,Ga.

My MOFO 261 wouldn’t run after removing the carb, pressing out the main jet for “opening” and reassembly.

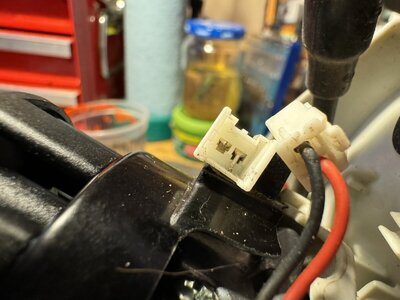

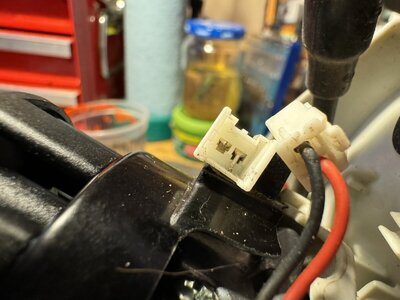

Saw flooded. Carb was removed a second time for inspection. Should go. But didn’t. I changed the solenoid. No joy. I hooked up the MDG1 and when it would not communicate with the control unit I found this. I had mash-*f-worded this connector and bent one of the tiny pins inside. It is very hard to straighten those little pins. This one looks straight but is L shaped. Blew most of the day on this. Oh well.

Saw flooded. Carb was removed a second time for inspection. Should go. But didn’t. I changed the solenoid. No joy. I hooked up the MDG1 and when it would not communicate with the control unit I found this. I had mash-*f-worded this connector and bent one of the tiny pins inside. It is very hard to straighten those little pins. This one looks straight but is L shaped. Blew most of the day on this. Oh well.