You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

White Death Corrosion Experts Needed

- Thread starter Agrarian

- Start date

-

- Tags

- 268xp corrosion white death

- Local time

- 7:01 PM

- User ID

- 232

- Joined

- Dec 24, 2015

- Messages

- 9,628

- Reaction score

- 66,501

- Location

- Coastal Oregon

Good thread. I'm in the same boat with an 084 case. This one may be too far gone to save though.

That one looks pretty rough. I'd have to see it in person to know if it can be saved or not. If the gasket sealing surface is compromised, you might be able to have it welded and then resurfaced.

Glock37

Pinnacle OPE Member

- Local time

- 10:01 PM

- User ID

- 356

- Joined

- Dec 31, 2015

- Messages

- 1,678

- Reaction score

- 6,852

- Location

- Monroeville Pa

Tell me if you paint the plastics parts of the husqvarna and if yes what you use

thank you

We dont do plastics

Even from new saws plastics dont match

Clean with liquid laudry soup it wont take the oils out of plastic

Sent from my iPhone using Tapatalk

Glock37

Pinnacle OPE Member

- Local time

- 10:01 PM

- User ID

- 356

- Joined

- Dec 31, 2015

- Messages

- 1,678

- Reaction score

- 6,852

- Location

- Monroeville Pa

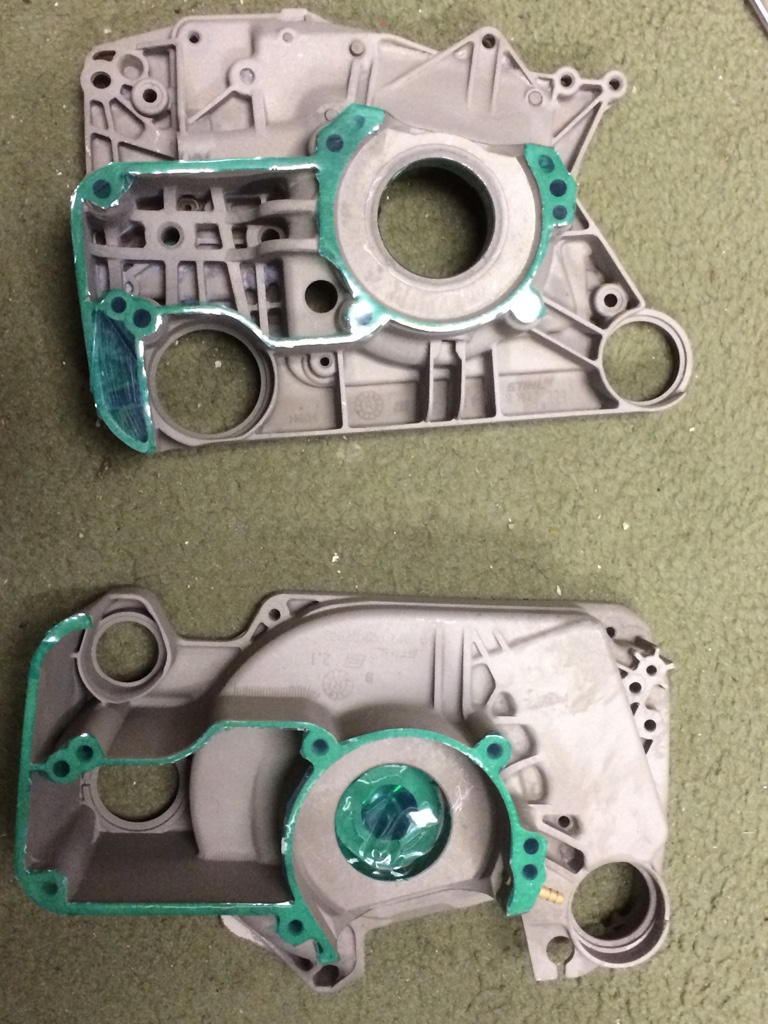

Good thread. I'm in the same boat with an 084 case. This one may be too far gone to save though.

View attachment 26452 View attachment 26453

Remove bearings it can be saved if its rotten into gasket area u will have to get it welded then blasted and powdered if not too deep may need built up with weld and finished A long process

Sent from my iPhone using Tapatalk

panteliss

Pinnacle OPE Member

- Local time

- 4:01 AM

- User ID

- 727

- Joined

- Jan 29, 2016

- Messages

- 633

- Reaction score

- 1,361

- Location

- Europe

Thank you sirWe dont do plastics

Even from new saws plastics dont match

Clean with liquid laudry soup it wont take the oils out of plastic

Sent from my iPhone using Tapatalk

Al Smith

Here For The Long Haul!

- Local time

- 10:01 PM

- User ID

- 537

- Joined

- Jan 14, 2016

- Messages

- 6,645

- Reaction score

- 14,807

- Location

- North western Ohio

Try baking soda and an old tooth brush.What you all are seeing is galvanic reaction between dissimilar metal.It acts like a battery in a way .Storing a saw for example on a concrete floor will hasten the process because of the blue clay component of Portland cement .Mag and aluminum are considered what's known as sacrificing metals and are very prone to this situation .I would think that there is a way to chemically neutralize the corrosion, and then seal with some form of epoxy.

Scrub the chit out of it,rinse it off ,change the bearings and run it .

Jon1212

Birch! Please.....

- Local time

- 8:01 PM

- User ID

- 315

- Joined

- Dec 29, 2015

- Messages

- 6,207

- Reaction score

- 35,710

- Location

- Utah, unfortunately.....

Try baking soda and an old tooth brush.What you all are seeing is galvanic reaction between dissimilar metal.It acts like a battery in a way .Storing a saw for example on a concrete floor will hasten the process because of the blue clay component of Portland cement .Mag and aluminum are considered what's known as sacrificing metals and are very prone to this situation .

Scrub the chit out of it,rinse it off ,change the bearings and run it .

Al,

Very good information. Especially in the use of a plastic bristled brush.

I think another mistake people make when trying to remove the corrosion is the use of carbon steel wire brushes and wheels.

I wonder if brass would be reactive with the magnesium.

Marshy

WFO Cutting

- Local time

- 10:01 PM

- User ID

- 417

- Joined

- Jan 5, 2016

- Messages

- 3,800

- Reaction score

- 13,109

- Location

- Mexico NY

Complete mechanical removal of corrosion products should be practiced insofar as practicable. Limit such mechanical cleaning to the use of stiff, hog bristle brushes, and similar nonmetallic cleaning tools (including nonwoven abrasive pads), particularly if treatment is to be performed under field conditions. Like aluminum, under no circumstances are steel or aluminum tools, steel, bronze oraluminum wool or other cleaningabrasive pads used on different metal surfaces to be used in cleaning magnesium. Anyentrapment of particles from steel wire brushes or steel tools, or contamination of treated surfaces by

dirty abrasives, can cause more trouble than the initial corrosive attack.

https://www.faa.gov/regulations_pol...craft/amt_handbook/media/FAA-8083-30_Ch06.pdf

- Local time

- 10:01 PM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,614

- Reaction score

- 63,350

- Location

- Strong Island NY

I have both here, may I ask why?What I would do and have done in thenpast is blast lightly down to bare metal then cover with Devcon epoxy. I prefer Devcon over JB by a wide margin.

Al Smith

Here For The Long Haul!

- Local time

- 10:01 PM

- User ID

- 537

- Joined

- Jan 14, 2016

- Messages

- 6,645

- Reaction score

- 14,807

- Location

- North western Ohio

I'm not so certain you have to do anything with it other than get the powder off .If it's a big concern maybe clean the crude real good and coat it with red Loctite .That stuff will stick to anything if the surface is clean. Once it sets up it isn't coming off .

Al Smith

Here For The Long Haul!

- Local time

- 10:01 PM

- User ID

- 537

- Joined

- Jan 14, 2016

- Messages

- 6,645

- Reaction score

- 14,807

- Location

- North western Ohio

Another thing that might work is easy off oven cleaner .Baking soda is a neutralizer but oven cleaner is acidic .Fact with some elbow grease it will remove aluminum transfer on a screwed up cylinder .You have to rinse it very well .Stinks to beat hell ,don't leave it on very long .

- Local time

- 7:01 PM

- User ID

- 5156

- Joined

- Jan 24, 2018

- Messages

- 9,545

- Reaction score

- 37,769

- Location

- Extreme Southeast CA

Chromic acid vs. baking soda - same results?

- Local time

- 10:01 PM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,389

- Reaction score

- 149,582

- Location

- East Jordan, MI

I cleaned up a spot (with a carbide burr) that had rotted through the oil tank on a 365. Smeared some jb weld over it and it’s held up fine and didn’t get worse. That was about five years agoChromic acid vs. baking soda - same results?

- Local time

- 7:01 PM

- User ID

- 5156

- Joined

- Jan 24, 2018

- Messages

- 9,545

- Reaction score

- 37,769

- Location

- Extreme Southeast CA

Glock37

Pinnacle OPE Member

- Local time

- 10:01 PM

- User ID

- 356

- Joined

- Dec 31, 2015

- Messages

- 1,678

- Reaction score

- 6,852

- Location

- Monroeville Pa

@Glock37 I can’t find the post…I think it was you who said what kind of soap to use or not use to not take the oil/shine out of paint…? I’m gonna put a bunch of parts in a dishwasher. Thanks!

Liquid laundry soap works cleaning plastic in hot water

Sent from my iPad using Tapatalk

- Local time

- 7:01 PM

- User ID

- 5156

- Joined

- Jan 24, 2018

- Messages

- 9,545

- Reaction score

- 37,769

- Location

- Extreme Southeast CA

Not dish soap right?Liquid laundry soap works cleaning plastic in hot water

Sent from my iPad using Tapatalk

Similar threads

- Replies

- 39

- Views

- 5K