Corrosion of Magnesium Alloys

Magnesium is the most chemically active of the metals used in aircraft construction and is the most difficult to protect. When a failure in the protective coating does occur, the prompt and complete correction of the coating failure is imperative if serious structural damage is to be avoided. Magnesium attack is probably the easiest type of corrosion to detect in its early stages, since magnesium corrosion products occupy several times the volume of the original magnesium metal destroyed. The beginning of attack shows as a lifting of the paint films and white spots on the magnesium surface. These rapidly develop into snow-like mounds or even “white whiskers.” [Figure 6-17] Re-protection involves the removal of corrosion products, the partial restoration of surface coatings by chemical treatment, and a reapplication of protective coatings.

Treatment of Wrought Magnesium Sheet and Forgings

Magnesium skin corrosion usually occurs around edges of skin panels, underneath washers, or in areas physically damaged by shearing, drilling, abrasion, or impact. If the skin section can be removed easily, this should be done to assure complete inhibition and treatment. If insulating washers are involved, screws should at least be sufficiently loosened, to permit brush treatment of the magnesium under the insulating washer. Complete mechanical removal of corrosion products should be practiced insofar as practicable. Limit such mechanical cleaning to the use of stiff, hog bristle brushes, and similar nonmetallic cleaning tools (including nonwoven abrasive pads), particularly if treatment is to be performed under field conditions. Like aluminum, under no circumstances are steel or aluminum tools, steel, bronze or aluminum wool or other cleaning abrasive pads used on different metal surfaces to be used in cleaning magnesium. Any entrapment of particles from steel wire brushes or steel tools, or contamination of treated surfaces by

dirty abrasives, can cause more trouble than the initial corrosive attack.

Corroded magnesium may generally be treated as follows:

1. Clean and strip the paint from the area to be treated. (Paint stripping procedures were discussed earlier in this chapter, and are also addressed in FAA

Advisory Circular (AC) 43.13-1B,

Acceptable

Methods, Techniques, and Practices — Aircraft

Inspection and Repair.)

2. Using a stiff, hog bristle brush or nonwoven abrasive pad, break loose and remove as much of the corrosion products as practicable. Steel wire brushes, carborundum abrasives, or steel cutting tools must not be used.

3. Treat the corroded area liberally with a chromic acid solution, to which has been added sulfuric acid, and work into pits and crevices by brushing the area while still wet with chromic acid, again using a nonmetallic brush.

4. Allow the chromic acid to remain in place for 5 to 20 minutes before wiping up the excess with a clean, damp cloth. Do not allow the excess solution to dry and remain on the surface, as paint lifting will be caused by such deposits.

5. As soon as the surfaces are dry, restore the original protective paint.

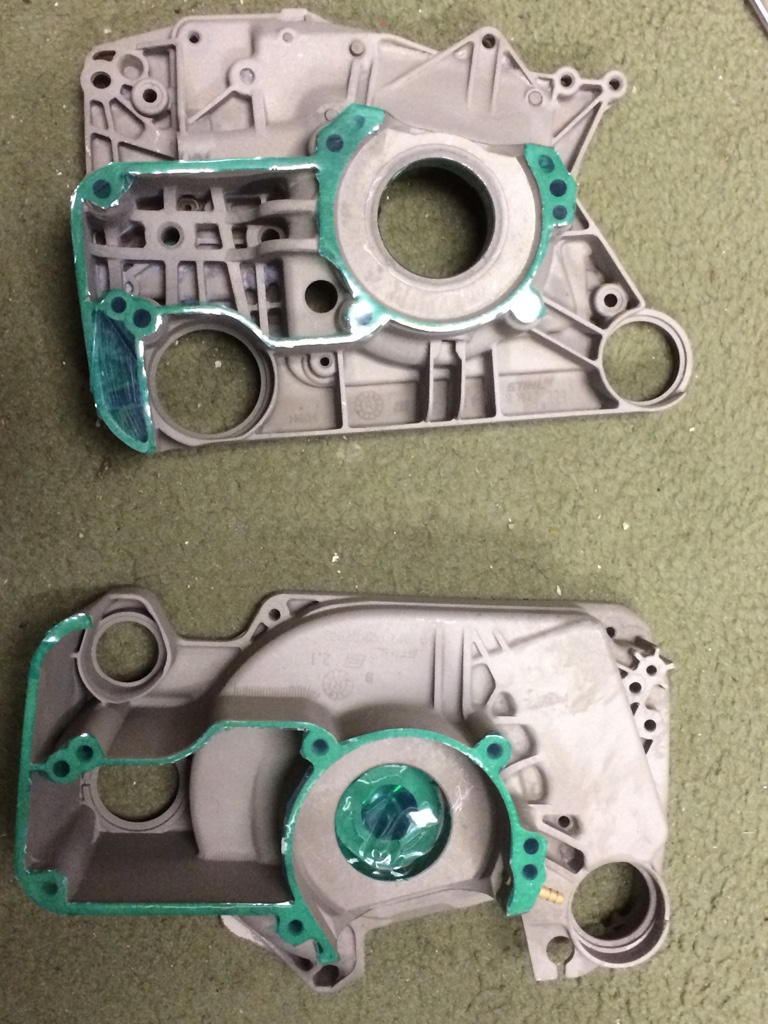

Treatment of Installed Magnesium Castings

Magnesium castings, in general, are more porous and more prone to penetrating attack than wrought magnesium skins. For all practical purposes, however, treatment is the same for all magnesium areas. Engine cases, bellcranks, fittings, numerous covers, plates, and handles are the most common magnesium castings. When attack occurs on a casting, the earliest practicable treatment is required if dangerous corrosive penetration is to be avoided. In fact, engine cases submerged in saltwater overnight can be completely

penetrated. If it is at all practicable, parting surfaces should be separated to effectively treat the existing attack and prevent its further progress. The same general treatment sequence in the preceding paragraph for magnesium skin should be followed. If extensive removal of corrosion products from a structural casting is involved, a decision from the manufacturer may be necessary to evaluate the adequacy of structural strength remaining. Specific structural repair manuals usually include dimensional tolerance limits for critical structural members and should be referred to, if any question of safety is involved.

https://www.faa.gov/regulations_pol...craft/amt_handbook/media/FAA-8083-30_Ch06.pdf